Linear Sorting Conveyors Drive Efficiency and Precision in Automated Logistics

Feb 12,2026

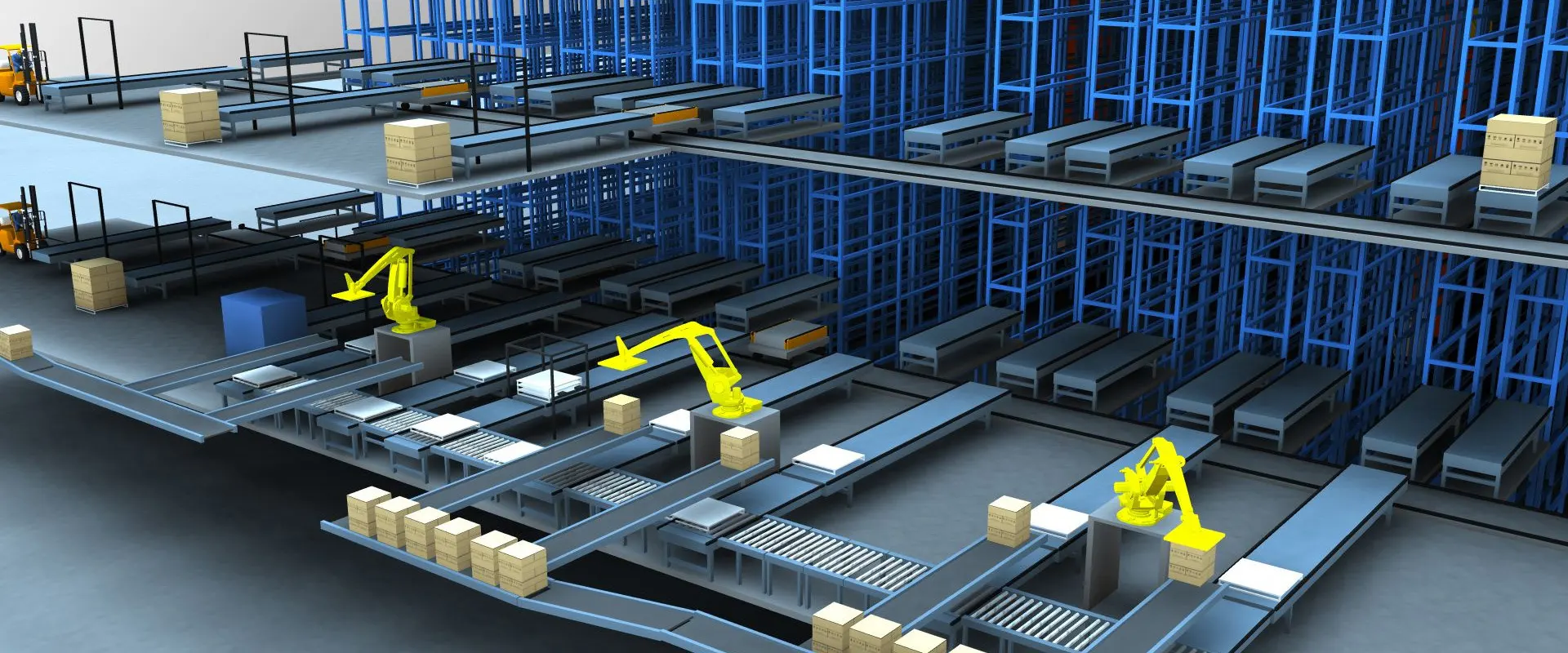

As logistics and supply chain operations continue to evolve toward higher levels of automation, Linear sorting conveyors have become a fundamental solution for achieving fast, accurate, and scalable material handling. Widely used in warehouses, distribution centers, and parcel hubs, linear sorting conveyors are helping logistics operators respond effectively to rising order volumes and increasing customer expectations.

Linear sorting conveyors are automated systems designed around a straight-line conveying structure. Items are transported along a linear conveyor path, where they are identified through barcode scanners or vision systems and then diverted to designated destinations using pushers, pop-up wheels, narrow belts, or other sorting mechanisms. This straightforward configuration enables predictable material flow and simplifies system control, making linear sorting conveyors highly reliable and easy to integrate into existing facilities.

One of the key advantages of linear sorting conveyors is their high throughput capability. Designed for continuous operation, these systems can process thousands of parcels per hour while maintaining consistent sorting accuracy. Their linear layout allows for multiple discharge points along the conveyor, enabling efficient sorting to a large number of destinations without interrupting product flow. This makes them particularly suitable for e-commerce fulfillment, retail distribution, and express logistics operations.

Flexibility is another major strength of linear sorting conveyors. Modular designs allow systems to be customized based on available space, throughput requirements, and product characteristics. Conveyor length, sorting stations, and divert types can be adjusted to accommodate different package sizes, weights, and shapes. This adaptability ensures that linear sorting conveyors remain effective even as business needs evolve.

From an operational perspective, linear sorting conveyors contribute significantly to labor reduction and cost efficiency. By automating repetitive sorting tasks, companies can reduce manual handling, minimize human error, and improve workplace safety. Automated sorting also leads to more consistent performance, helping logistics facilities maintain service levels during peak periods such as seasonal sales or promotional events.

Linear sorting conveyors also support better space utilization within warehouses. Their straight-line configuration makes layout planning straightforward and allows systems to be installed along walls, between storage zones, or integrated with upstream and downstream equipment such as scanners, packing stations, and shipping lines. This streamlined layout improves overall material flow and reduces congestion on the warehouse floor.

Looking ahead, the development of linear sorting conveyors is closely aligned with the growth of smart logistics technologies. Integration with warehouse management systems (WMS), real-time data monitoring, and intelligent control software will further enhance sorting efficiency and transparency. As automation continues to advance, linear sorting conveyors will remain a reliable and cost-effective solution for modern logistics operations.

In conclusion, Linear sorting conveyors play a critical role in today’s automated logistics environment. By combining high throughput, flexible configuration, and operational reliability, they enable businesses to optimize sorting processes and remain competitive in an increasingly demanding supply chain landscape.

PREVIOUS: