Belt Sorting Conveyor Machine Accelerates Automation in Modern Logistics

Feb 10,2026

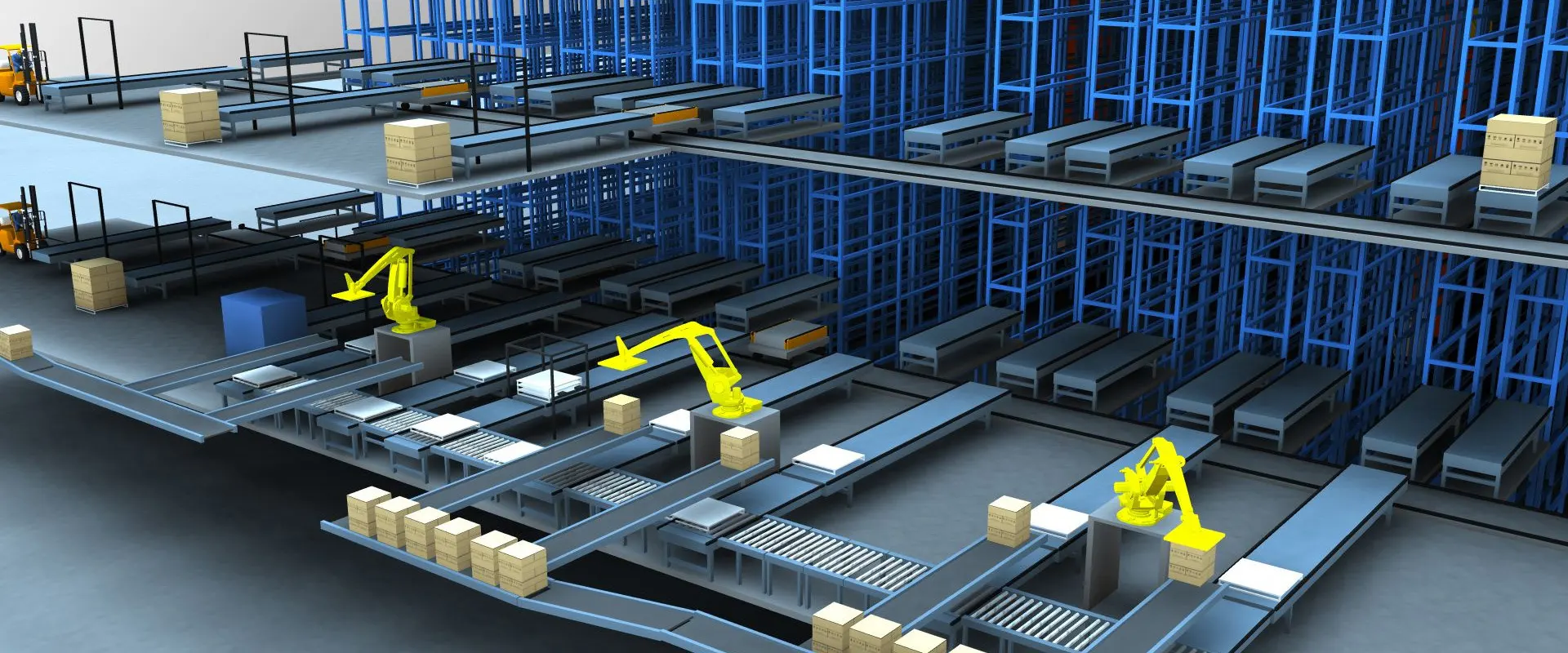

As global logistics operations continue to scale at an unprecedented pace, the belt sorting conveyor machine has emerged as a critical technology enabling fast, accurate, and automated parcel handling. Widely adopted in e-commerce fulfillment centers, courier hubs, and warehouse distribution systems, belt sorting conveyor machines play a vital role in meeting growing demands for speed, reliability, and operational efficiency.

A belt sorting conveyor machine is an automated sortation system that uses continuous moving belts to transport items and divert them to designated destinations based on predefined sorting logic. Packages are scanned, identified, and guided smoothly along the conveyor line, where controlled belt movements or diverters ensure precise discharge at the correct chute or lane. Compared with manual sorting or conventional conveyor solutions, this approach significantly improves throughput while minimizing human error.

One of the main advantages of a belt sorting conveyor machine is its ability to handle a wide range of package types. From small parcels and polybags to cartons and irregularly shaped goods, belt-based sorting systems offer stable conveying and gentle handling, reducing the risk of product damage. This versatility makes them particularly suitable for industries with diverse order profiles, such as retail, apparel, electronics, and third-party logistics.

Efficiency is another key benefit driving the adoption of belt sorting conveyor machines. These systems are designed for continuous operation, allowing thousands of items per hour to be sorted with consistent accuracy. Automated control systems synchronize belt speed, scanning equipment, and sorting logic to maintain smooth material flow even during peak periods. As a result, logistics operators can process higher order volumes without expanding labor resources or floor space.

Space optimization is increasingly important in modern warehouses, and belt sorting conveyor machines offer flexible layout options to address this challenge. Modular designs allow systems to be customized to fit specific facility constraints, whether installed in straight lines, curves, or multi-level configurations. This adaptability enables businesses to maximize available space while maintaining high sorting performance.

In addition to productivity gains, belt sorting conveyor machines contribute to long-term cost reduction. Automation reduces dependence on manual labor, lowers error-related rework, and improves overall operational consistency. Integrated monitoring and diagnostics functions also support preventive maintenance, helping minimize downtime and extend equipment lifespan.

Looking ahead, the evolution of belt sorting conveyor machines is closely tied to smart logistics development. Integration with warehouse management systems (WMS), real-time data analytics, and intelligent vision technologies will further enhance sorting accuracy and system responsiveness. These advancements will enable logistics facilities to adapt quickly to fluctuating demand and increasingly complex distribution networks.

In conclusion, the belt sorting conveyor machine represents a foundational solution in the automation of modern logistics. By combining speed, accuracy, flexibility, and scalability, it empowers businesses to optimize sorting operations and remain competitive in an increasingly fast-paced supply chain environment.

PREVIOUS: