Narrow Belt Sorter Conveyor Systems Enhance High-Speed Logistics Efficiency

Feb 06,2026

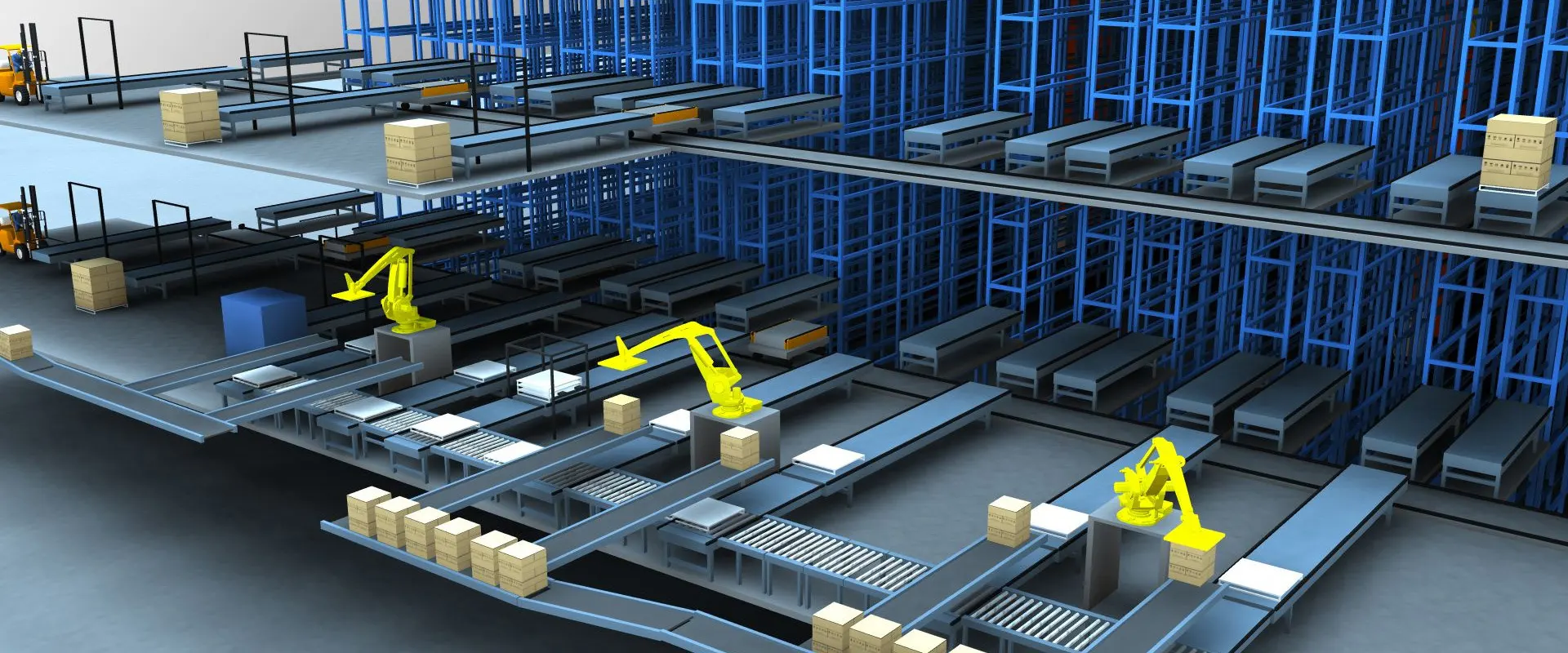

In the era of rapid growth in e-commerce and automated logistics, narrow belt sorter conveyor systems are emerging as one of the leading solutions for high-speed, high-accuracy package sortation. These advanced conveyors provide compact, efficient, and reliable sorting performance for warehouses, distribution centers, and fulfillment hubs facing rising demand for rapid order processing and delivery.

A narrow belt sorter conveyor is a linear sortation system composed of multiple narrow motorized belt sections that transport items along a straight conveyor path. Each belt section operates independently to carry packages, and when an item reaches its designated sort point, automated mechanisms like pushers or gates divert the package onto corresponding chutes or conveyors. This design enables fast, continuous sorting with minimal space usage, making the technology ideal for high throughput applications such as e-commerce, retail distribution, and express logistics.

Shenzhen Weipaitengda Technology Co., Ltd. offers a cutting-edge example of this sortation technology in its Narrow Belt Sorting Conveyor product. Designed for high-speed, high-accuracy operations, this conveyor system features motorized cross-belt conveyors arranged in a straight line to handle a variety of item types including parcels, boxes, and irregularly shaped packages. Its automated divert mechanisms help streamline sortation tasks, reduce manual labor and maintain reliable performance even during peak demand periods.

The technical parameters of the Weipaitengda Narrow Belt Sorting Conveyor demonstrate the system’s capability for large-scale logistics operations. It supports flexible customizations such as slot numbers, carrier sizes, and grid widths depending on facility requirements, and can achieve main line speeds up to 2.0 m/s and running speeds up to 2.5 m/s. The system’s sorting capacity reaches 12,000 parcels per hour on one side and 24,000 parcels per hour on two sides, with a theoretical maximum of up to 40,000 orders per hour under optimal conditions. Package weight ranges from 0.01 kg up to 35 kg, and barcode reading accuracy exceeds 99%, while sorting errors remain extremely low. This combination of high speed and precision makes the system suitable for logistics environments with demanding throughput targets.

Narrow belt sorter conveyors deliver key advantages beyond raw processing capacity. Their compact footprint and modular design allow for adaptability to different warehouse layouts, helping facilities optimize floor space while improving sortation accuracy. Compared to traditional tilt-tray or pop-up wheel sorters, narrow belt sorters reduce conveyor length requirements, enabling more discharge points in limited space. Continuous flow design also supports gentle handling of products, which reduces item damage rates and improves overall operational efficiency.

Industry adoption of narrow belt sorters has grown alongside the rise of automation and real-time warehouse management systems (WMS). By integrating with advanced scanning technologies and control software, these conveyors provide real-time tracking and analytics, enabling predictive maintenance and minimizing operational downtime. Accuracy enhancements and data-driven decision making help logistics managers achieve higher productivity with fewer manual interventions.

In practical applications, narrow belt sorter conveyors excel in space-constrained environments that require high throughput. Their ability to handle diverse package types, from small envelopes to medium cartons, makes them valuable assets in postal distribution centers, retail networks, and third-party logistics (3PL) operations. During peak seasons like holiday surges or major online sales events, these systems help businesses cope with sharp increases in order volume without sacrificing accuracy or speed.

Looking to the future, narrow belt sorter conveyors are expected to integrate even more intelligent features, including advanced vision systems and AI-powered routing algorithms. These developments will further enhance sortation throughput and accuracy while helping warehouses adapt dynamically to shifting demand patterns. As logistics networks continue to evolve, narrow belt sorters will play an increasingly vital role in meeting the challenges of modern supply chain automation.

In summary, narrow belt sorter conveyor systems represent a strategic investment for logistics operations aiming to boost sorting efficiency, maximize space utilization, and maintain exceptional accuracy. With products like the Narrow Belt Sorting Conveyor from Shenzhen Weipaitengda Technology Co., Ltd., businesses can achieve high-speed sortation that meets today’s competitive delivery expectations.

PREVIOUS: