Ring Sorting Conveyor Systems Revolutionize High-Volume Logistics Operations

Feb 06,2026

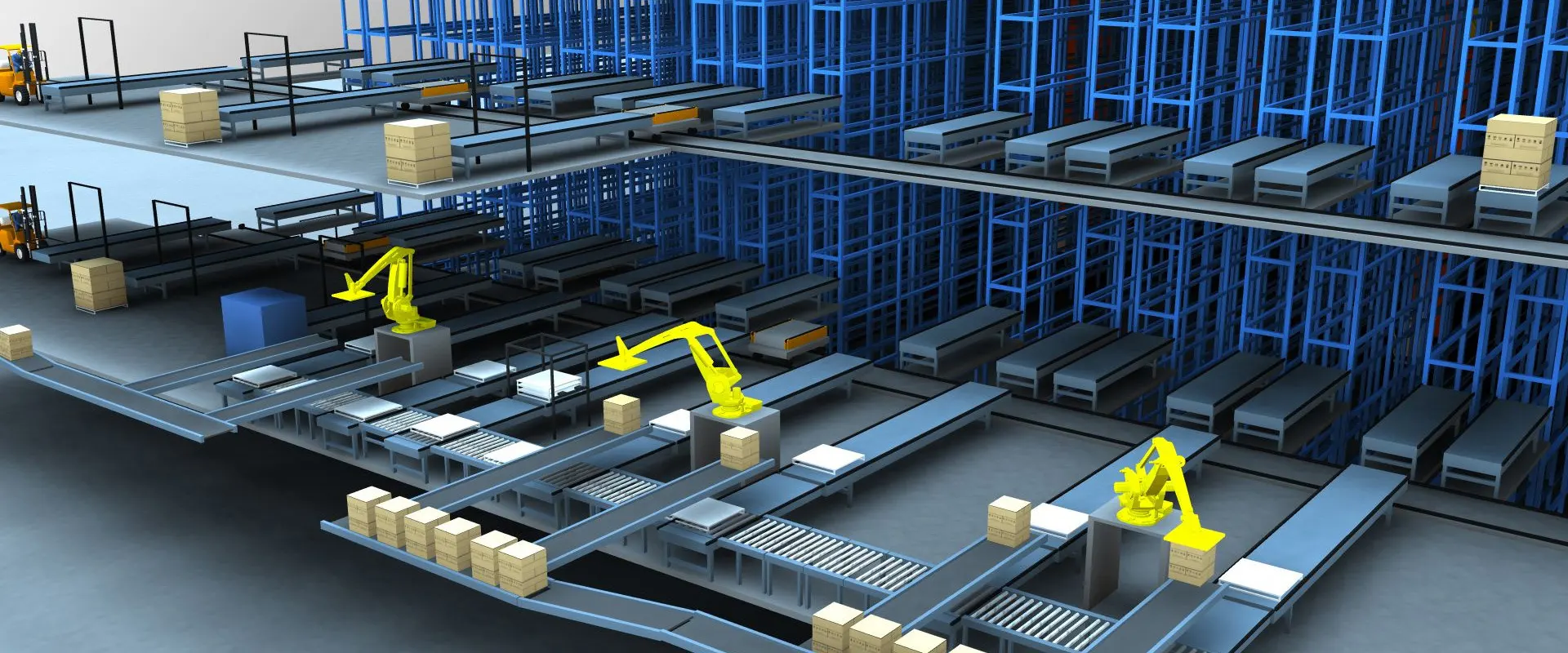

Ring sorting conveyor systems are rapidly transforming the landscape of modern logistics and distribution, driven by the surging demands of e-commerce, express delivery, and automated warehousing. These innovative systems deliver unmatched speed, accuracy, and efficiency for high-volume package handling, marking a significant step forward in the automation of supply chains worldwide.

At the core of this trend are ring sorting conveyor systems, a specialized form of automated sortation technology where conveyor modules travel on a continuous circular track. Unlike traditional linear sorters, ring systems maximize available floor space while providing continuous, uninterrupted sorting cycles. Their modular structure enables dynamically routing packages based on predefined criteria such as destination, size, or priority, reducing manual intervention and increasing overall throughput.

An outstanding example of this technology is the High-efficiency Circular Sorting Line for Large-capacity Package offered by Shenzhen Weipaitengda Technology Co., Ltd. This circular cross-belt sortation solution is engineered specifically for high-traffic distribution centers, parcel hubs, and e-commerce fulfillment facilities that must handle thousands of items per hour with precision, reliability, and adaptability.

The circular design incorporates motorized cross-belt conveyors mounted on a ring track, allowing packages to be diverted automatically to multiple destinations. This continuous sorting approach not only saves valuable space but also significantly reduces system bottlenecks compared to traditional straight line setups. With a main line speed reaching up to 2.0 m/s and a theoretical throughput capacity of up to 40,000 orders per hour under optimal conditions, ring sorting conveyor systems deliver performance levels that meet even peak operational demands.

One of the most compelling advantages of ring sorting conveyor systems is their ability to handle a diverse range of package types. The High-efficiency Circular Sorting Line supports weights from as light as 0.1 kg up to 35 kg, accommodating envelopes, plastic bags, cartons, and irregular items without compromising accuracy. Crucially, barcode reading accuracy can exceed 99%, and sorting errors remain below 0.01%, ensuring that parcels are routed correctly the first time.

Beyond raw throughput, these systems offer remarkable configurability. Facility layout constraints can be addressed with customizable carrier sizes, grid widths, and line heights, enabling each installation to reflect the unique operational requirements of a specific warehouse or distribution center. Automated pushers and gates work in harmony with integrated controls to manage package flow seamlessly, providing operators with increased visibility and control over sortation tasks.

The economic impact of ring sorting conveyor systems is equally significant. By automating labor-intensive sorting tasks, companies can drastically reduce workforce costs while boosting productivity. Fewer manual steps translates to fewer human errors and improved long-term reliability. Moreover, the space-saving footprint of the circular track design makes it possible to optimize facility layouts and improve material flow, contributing to better resource utilization and lower operational expenses.

In practical applications, ring sorting conveyor systems have helped distribution hubs respond effectively to fluctuating package volumes, especially during peak seasons and promotional events where order surges can severely strain conventional operations. Their high throughput and dynamic routing capabilities make them indispensable for modern logistics centers seeking competitive advantages in processing speed and delivery accuracy.

As technology continues to advance, ring sorting conveyor systems are expected to integrate even more intelligent features. Future developments may include advanced machine-vision scanning, AI-driven routing optimization, and predictive maintenance analytics, further enhancing operational efficiency and reducing downtime. This convergence of automation and intelligence positions ring sorting conveyor systems as pivotal components in the future of smart logistics infrastructure.

In summary, ring sorting conveyor systems represent a transformative force in logistics automation. With solutions like the High-efficiency Circular Sorting Line for Large-capacity Package, companies can achieve higher throughput levels, superior handling accuracy, and greater adaptability to evolving supply chain challenges. As e-commerce and global trade continue to expand, these innovative systems will play a central role in shaping the next generation of logistics excellence.