Product Introduction

Linear Sorting Conveyor: An Efficient Solution for Material Sorting

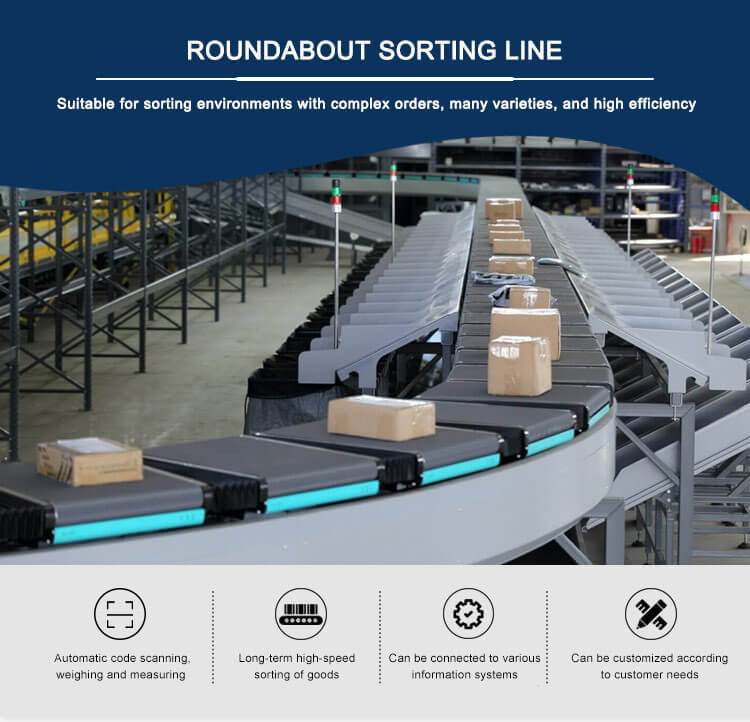

A linear sorting conveyor is a crucial piece of equipment in various industries, designed to streamline the process of sorting and transporting items.

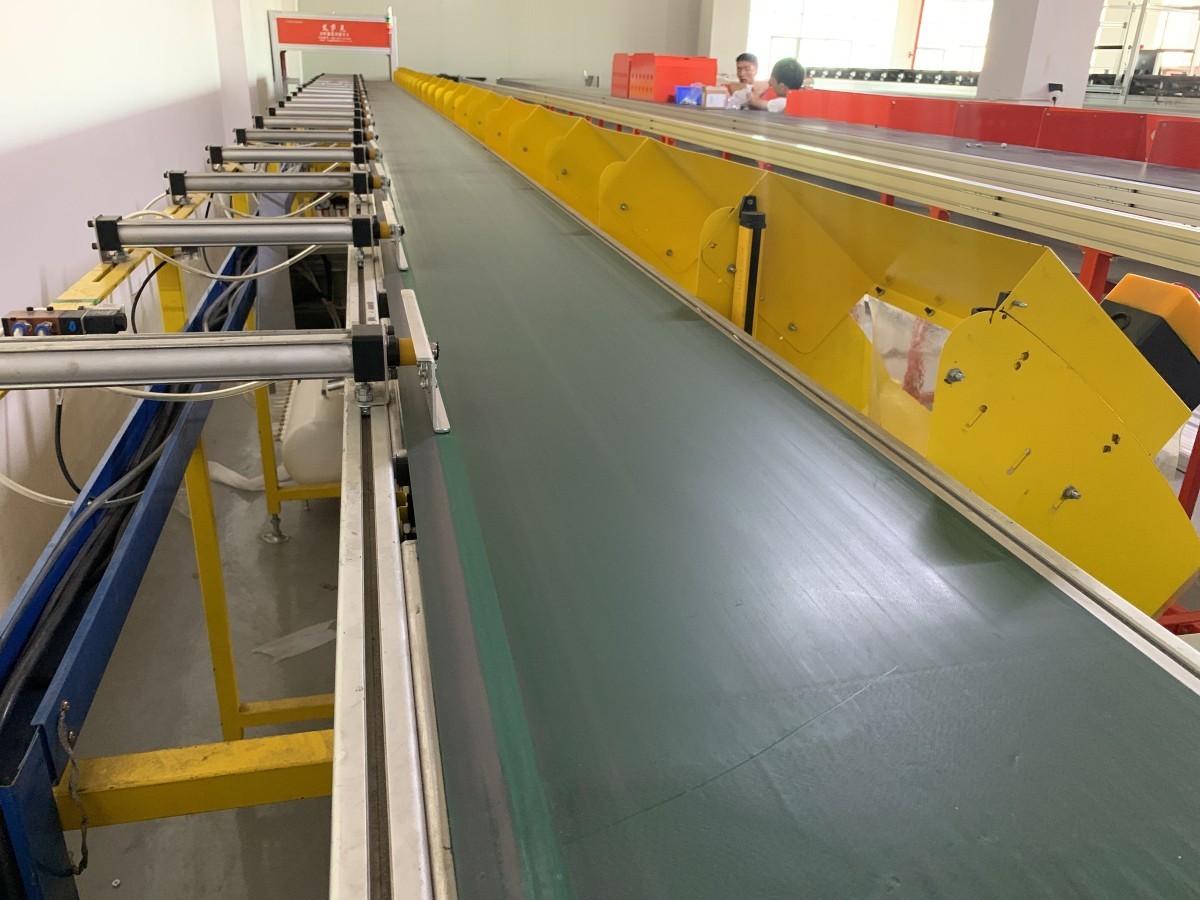

1. Design and Structure

The conveyor typically consists of a long, straight belt or series of rollers mounted on a sturdy frame. The length of the conveyor can be customized according to the specific requirements of the application. It is often made of high - quality materials such as stainless steel or durable polymers to ensure long - term reliability and resistance to wear and tear. The surface of the conveyor belt or rollers is smooth, allowing for seamless movement of the items being sorted.

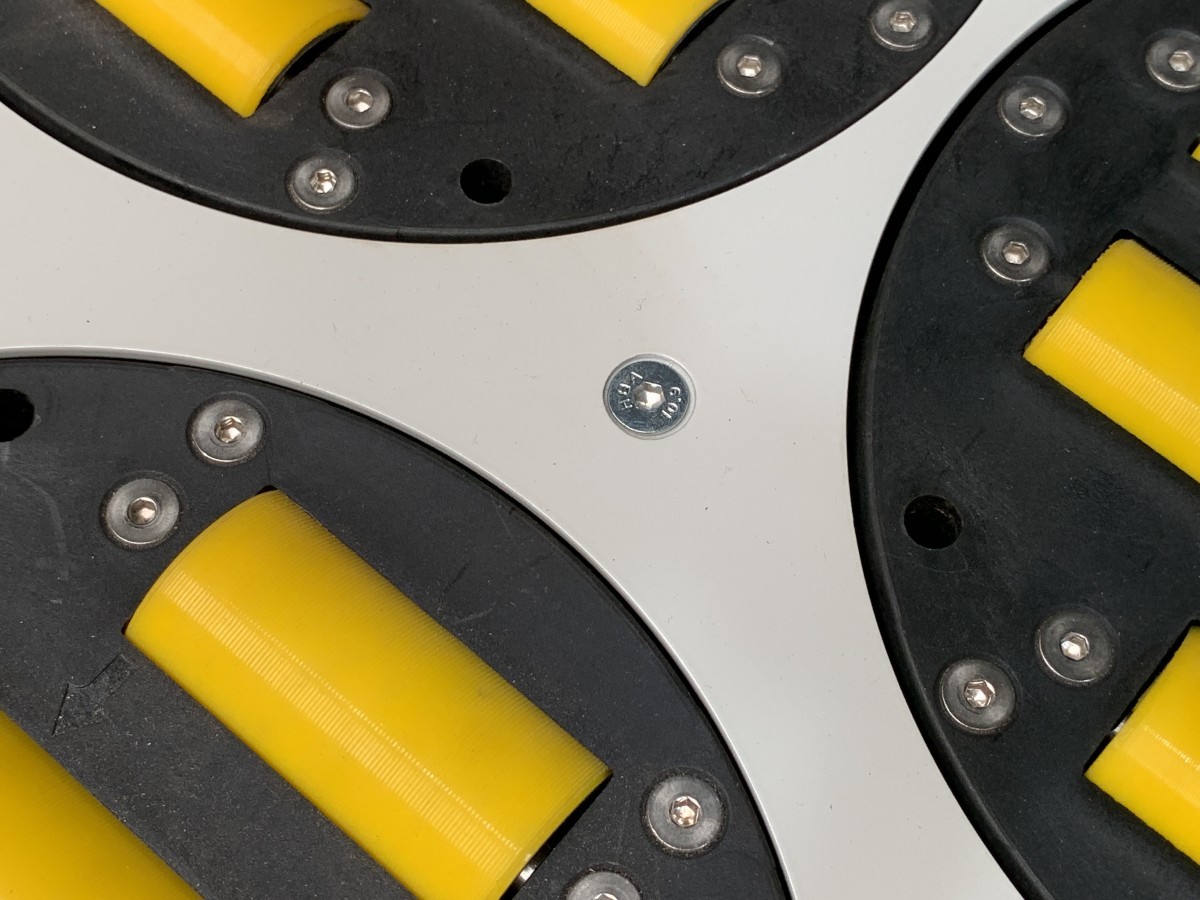

2. Sorting Mechanism

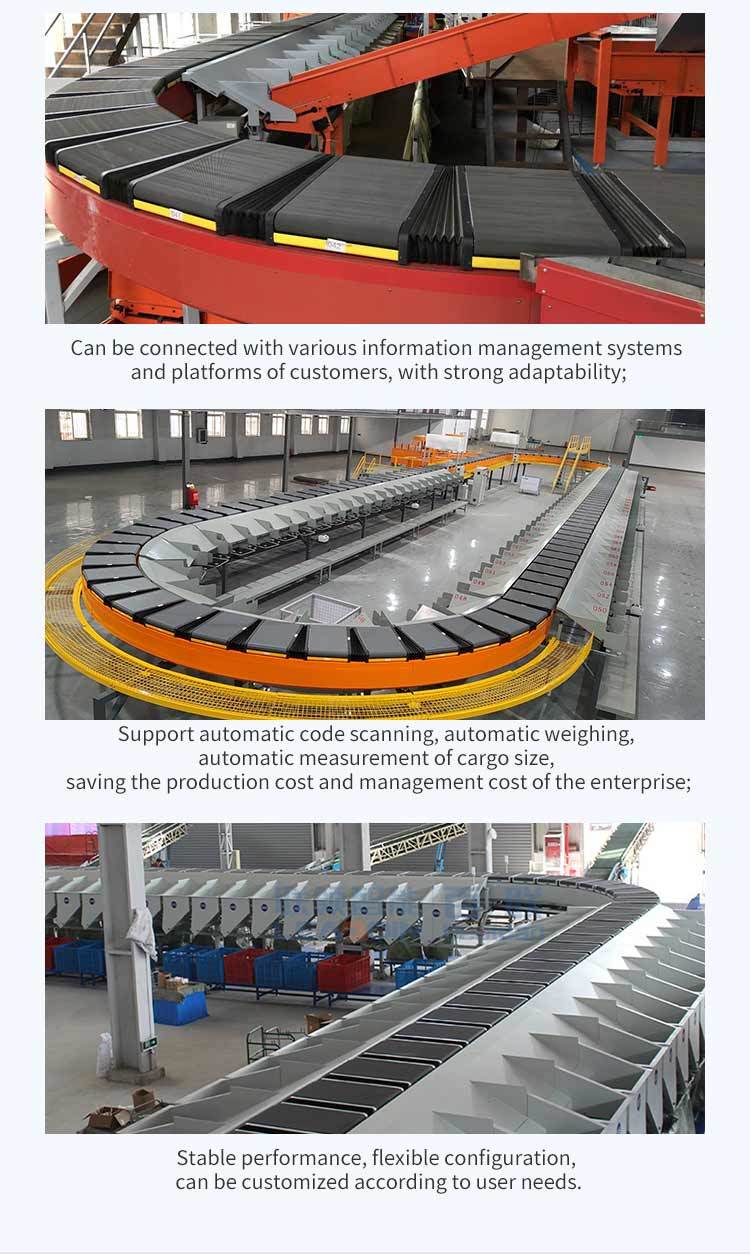

One of the key features of the linear sorting conveyor is its sorting mechanism. It can be equipped with sensors, such as optical sensors or proximity sensors. These sensors are strategically placed along the conveyor line. When an item passes by a sensor, the sensor detects certain characteristics of the item, such as its size, shape, color, or barcode. Based on this information, the conveyor system can then divert the item to different output channels or bins. For example, in a manufacturing plant, products of different models can be sorted based on their unique shapes detected by the sensors.

3. Adjustable Speed and Direction

The linear sorting conveyor offers flexibility in terms of speed and direction. The speed of the conveyor can be adjusted to match the production rate of the upstream and downstream processes. A slow - speed setting may be used for delicate or fragile items, while a higher speed can be applied for more robust products when a faster sorting process is required. Additionally, in some advanced models, the conveyor can be programmed to change direction, which is useful for situations where items need to be re - routed or re - sorted.

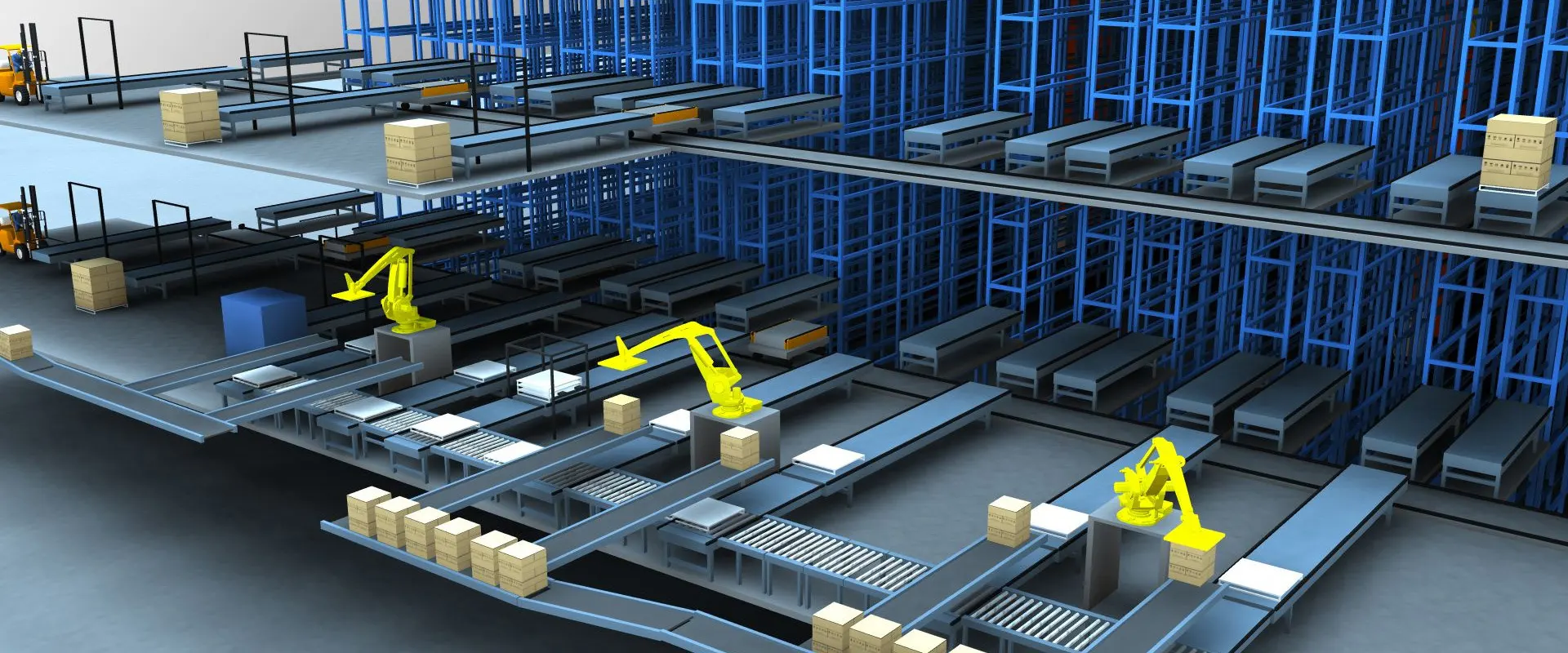

4. Applications

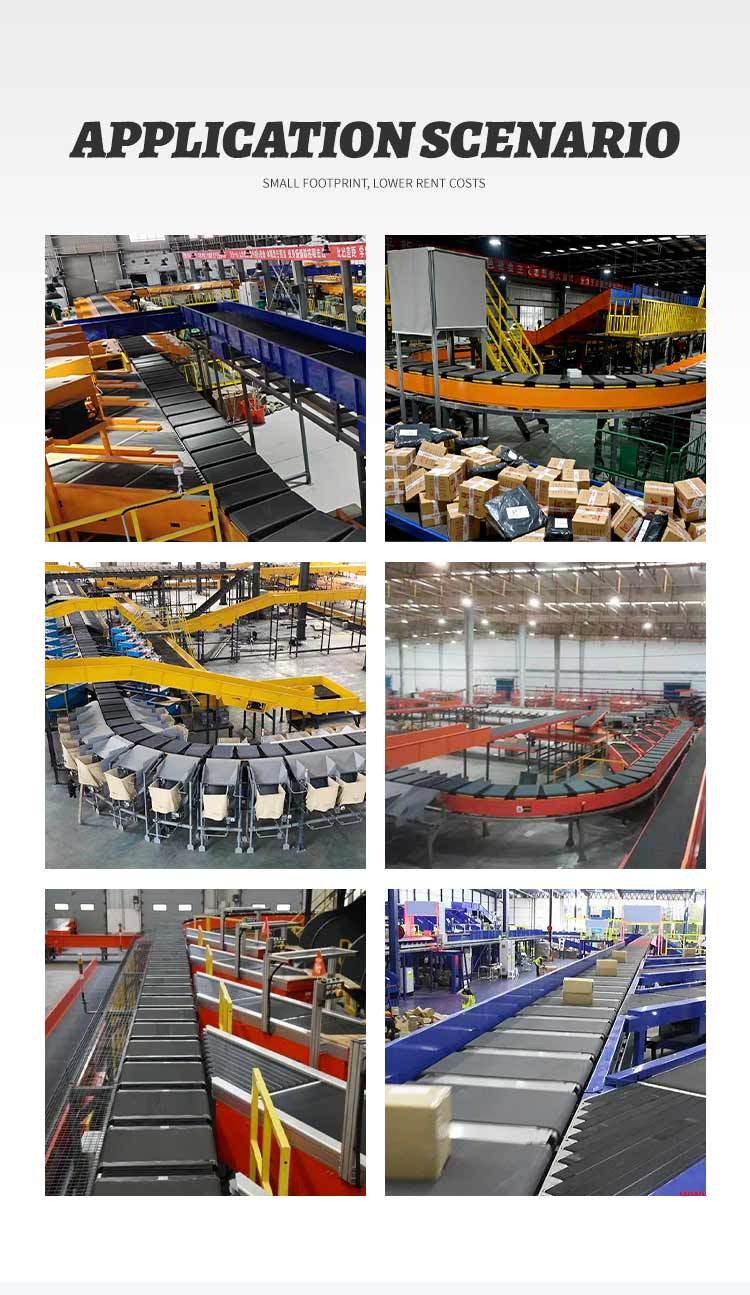

Logistics and Warehousing: In a large warehouse, linear sorting conveyors are used to sort packages according to their destinations. This helps in quickly and accurately preparing shipments and reduces the time and labor required for manual sorting.

Manufacturing: It is used to sort components during the production process. For instance, in an electronics manufacturing factory, different types of circuit boards can be sorted based on their functionality or quality levels.

Food Processing: The conveyor can be used to sort food items such as fruits and vegetables. For example, ripe and unripe fruits can be separated based on their color or size, ensuring that only high - quality products are packaged for sale.

5. Benefits

Increased Efficiency: By automating the sorting process, it significantly reduces the time and effort required compared to manual sorting. This leads to higher productivity and throughput in the overall operation.

Accuracy: The use of sensors and precise control systems ensures a high level of accuracy in sorting. Fewer errors mean less waste and better quality control.

Space - Saving: Linear sorting conveyors are designed to be compact and can be integrated into existing production or warehousing layouts, making efficient use of space.

In conclusion, the linear sorting conveyor is an innovative and indispensable tool for industries that deal with the sorting and transportation of various items. Its advanced features, including the sorting mechanism, adjustable speed and direction, and wide range of applications, make it a valuable asset for improving efficiency, accuracy, and overall productivity.

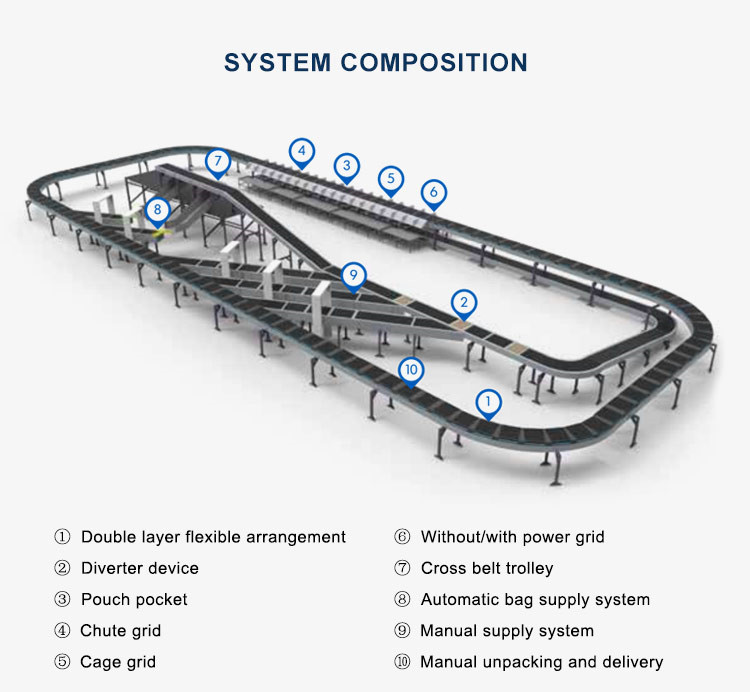

The Linear Cross Belt Sorter is an advanced sorting system that uses motorized cross-belt conveyors arranged in a straight line to transport and sort products efficiently. Items are moved along individual belts and are diverted to specific chutes or conveyors using automated mechanisms like pushers or gates. It is designed for high-speed, high-accuracy sorting of various product types, including parcels, boxes, and irregularly shaped items. Commonly used in e-commerce, logistics, and retail distribution, the Linear Cross Belt Sorter offers high throughput, reduces manual labor, and ensures reliable, precise sorting, making it ideal for large-scale sorting operations.

Parameter

| Product name | Cross belt sorter |

| Number of slots | 180 (can be customized) |

| Grid width | 750mm |

| Number of cars | Customized according to needs |

| Car size | 428*700mm |

| Main line speed | 2.0m/s |

| Supply table speed | 21600 single/hour(12 people in two zones for package) |

| Line height | 1.9m (can be customized) |

| Package weight range | 0.1-10kg |

| Package size (Minimum) | L100mm*W100mm*H10mm |

| Package size (Maximum) | L400mm*W400mm*H350mm |

| Sorting time limit | Actual 18000-21000, theoretical 40000 orders/ hours |

| Running speed | 2.5m/s max |

| Sorting capacity | 12000pph for one side, 24000pph for two side |

| Capacity for each induction | >2000pph |

| Carrier size | 500*700mm, 600*700mm,800*1100mm, customized |

| Load capacity | 0.01-35kg |

| Dimension for package | 100*100*1-600*1000*250mm per the dimension of carriers |

| Sorting error | ≤0.01% |

| Bar-code reading | >99% |

| Noise | <72BD |

| Package | Envelope, plastic bag, carton, etc. suitable for kinds of package. |

Details Show

Product Video

Details Show

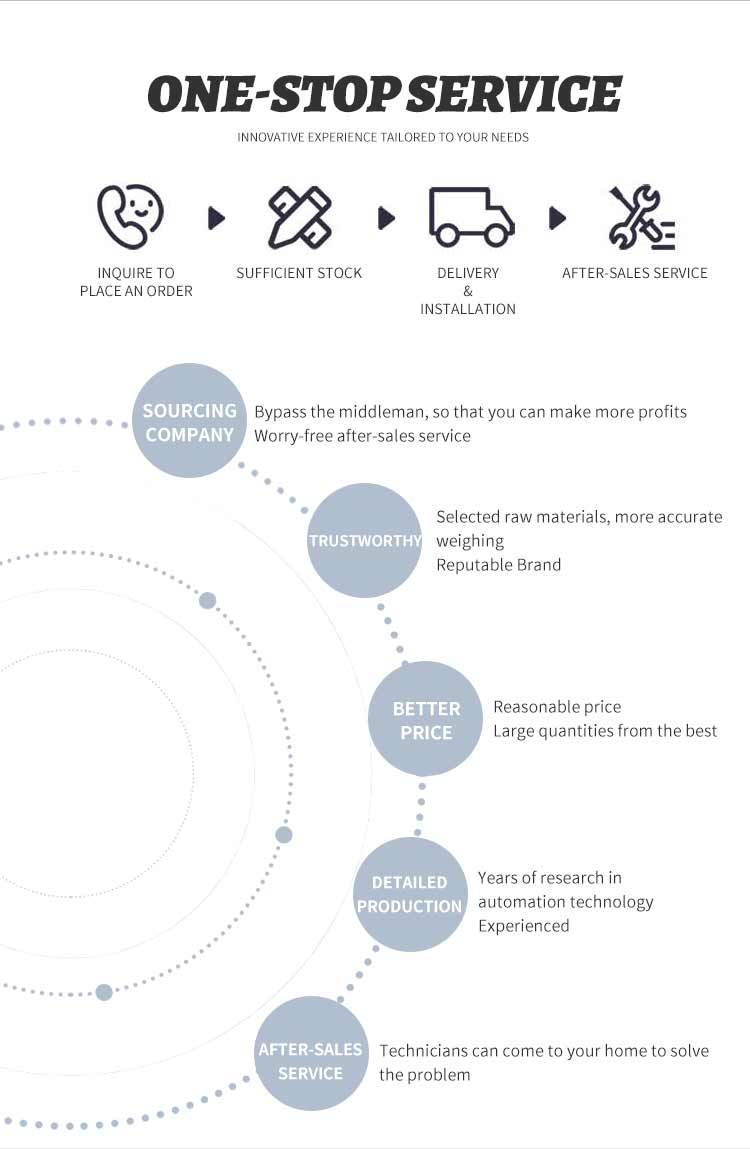

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices.

OUR EXHIBITION

We welcome customers at home and abroad to visit our factory to reach long-term cooperation and create success together.

Customer Feedback

We welcome customers at home and abroad to visit our factory to reach long-term cooperation and create success together.

Certificate

We welcome customers at home and abroad to visit our factory to reach long-term cooperation and create success together.

FAQ

Q1. What is your payment term?

A1: Payment terms is T/T or other reasonable payment is acceptable.

Q2. How many days of the lead time for standard machine?

A2: We have stock or 2 working days.

Q3.Custom made service is available?

A3:Yes,we can customize all the machines.

Q4. Can you help us contact the shipping agent in your loading port?

A4: Yes, we have forwarders who always provide us with the best service and prices.

Q5: How to fix the problem if the equipment fails in working?

A5: Take a video to us first,we can guide you to handle the problem by video. we can also provide new spare parts if necessary.

Q6: How long time of your warranty period?

A6: Standard is 12months,but we also can giving 24months(2years) if there are specification situation.

Linear Sorting Conveyor

Categories:

Keywords:

Online Message

Ready to grow your business? Your next great business opportunity starts with an inquiry.