Automatic Sorting Conveyor Systems Redefine Speed and Accuracy in Modern Logistics

Feb 18,2026

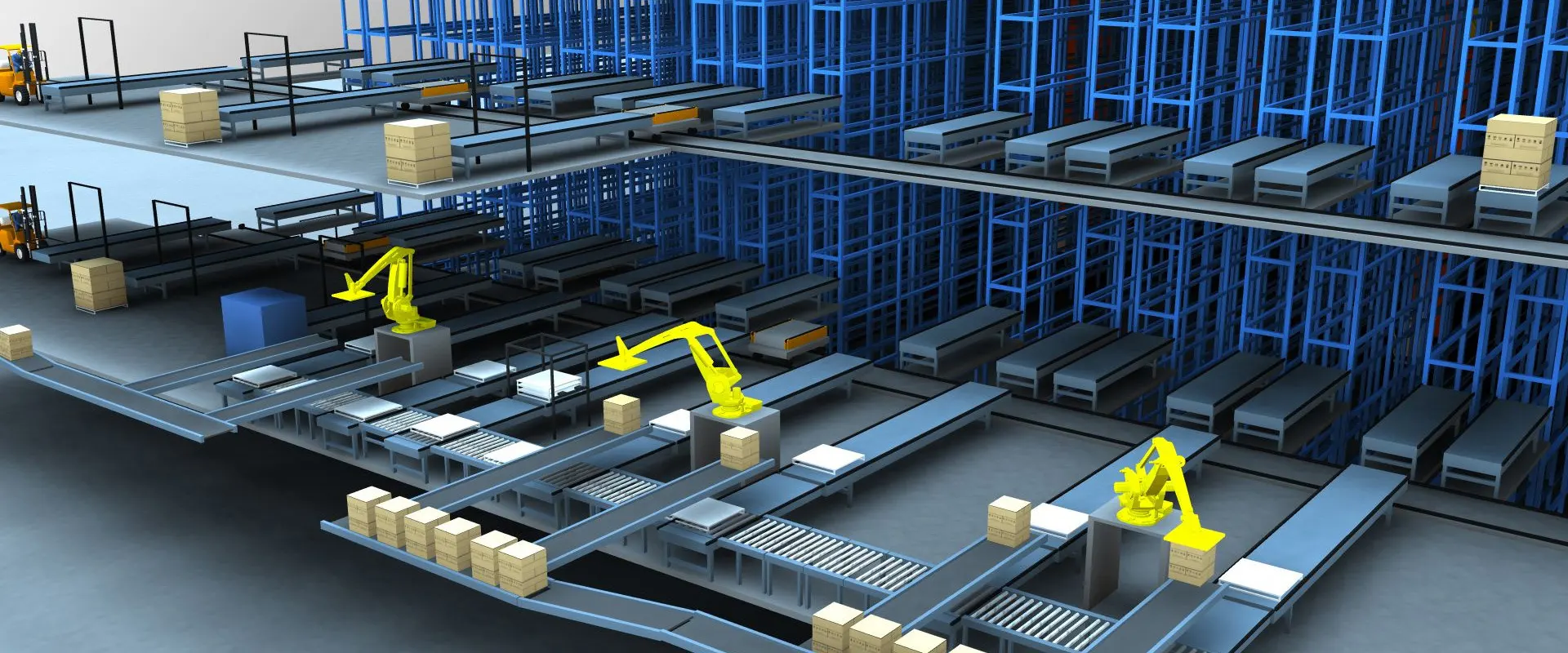

With the rapid expansion of e-commerce, express delivery, and global supply chains, the automatic sorting conveyor has become a cornerstone technology in modern logistics automation. Designed to process large volumes of parcels with high speed and precision, automatic sorting conveyors are helping logistics operators improve efficiency, reduce costs, and meet rising customer expectations for fast and accurate delivery.

An automatic sorting conveyor is an integrated system that combines conveying, identification, and sorting functions into a seamless workflow. Items moving along the conveyor are automatically scanned using barcode readers or vision systems, after which control software determines the correct destination and activates sorting mechanisms such as pushers, belts, diverters, or sliding shoes. This automated process replaces manual sorting tasks, significantly increasing throughput while minimizing human error.

One of the primary advantages of an automatic sorting conveyor is its ability to operate continuously under high workloads. These systems can sort thousands of items per hour with stable accuracy, even during peak periods such as promotional campaigns or seasonal sales. By maintaining consistent performance, automatic sorting conveyors enable distribution centers to handle fluctuating order volumes without compromising service quality.

Automatic sorting conveyors are also valued for their versatility. They can handle a wide range of items, from small parcels and polybags to cartons and irregularly shaped packages. Gentle conveying and controlled diversion reduce product damage, making these systems suitable for industries such as retail, apparel, electronics, pharmaceuticals, and third-party logistics. Modular system designs further allow customization to match specific facility layouts and operational requirements.

From a cost perspective, investing in an automatic sorting conveyor delivers long-term benefits. Automation reduces reliance on manual labor, lowers training requirements, and decreases sorting errors that lead to rework or returns. In addition, integrated monitoring systems support preventive maintenance, improving equipment reliability and extending service life while minimizing unplanned downtime.

Space efficiency is another key benefit. Automatic sorting conveyors can be configured in linear, curved, or looped layouts, allowing facilities to optimize available floor space. Their ability to integrate with upstream and downstream systems—such as induction lines, packing stations, and shipping conveyors—helps create smooth material flow across the entire logistics operation.

As logistics technology continues to evolve, automatic sorting conveyors are becoming increasingly intelligent. Integration with warehouse management systems (WMS), real-time data analytics, and smart control software enables greater visibility, faster decision-making, and more responsive operations. These advancements position automatic sorting conveyors as essential components of smart logistics and automated distribution centers.

In conclusion, the automatic sorting conveyor plays a vital role in the transformation of modern logistics. By delivering speed, accuracy, flexibility, and scalability, it empowers businesses to optimize sorting operations and remain competitive in a fast-moving and demand-driven supply chain environment.

PREVIOUS: