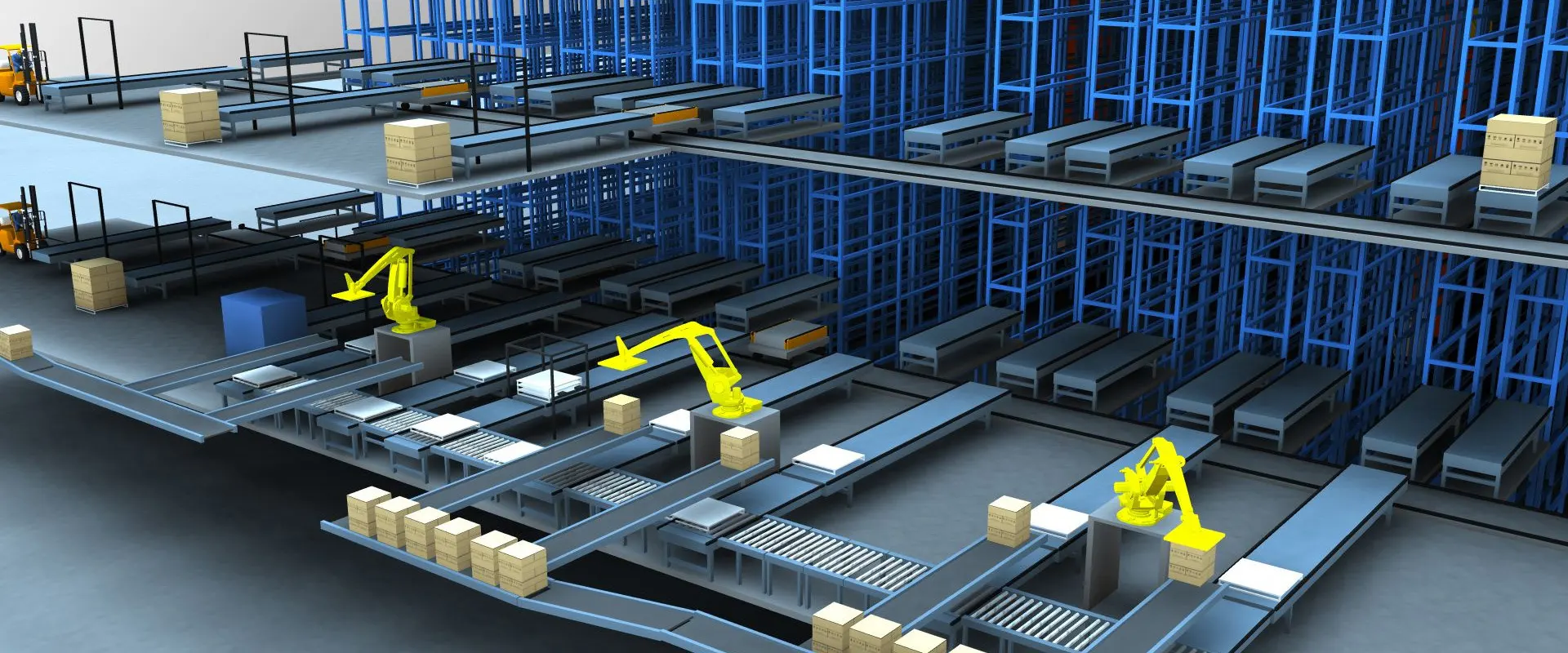

DWS System Sorter Conveyor Accelerates Smart Logistics Transformation

Feb 13,2026

As global e-commerce continues to expand at record speed, logistics providers are under increasing pressure to improve accuracy, speed, and efficiency. One technology drawing significant attention across the supply chain industry is the DWS system sorter conveyor, an integrated solution designed to automate dimensioning, weighing, and scanning processes within a single platform.

Industry analysts note that the rapid growth of parcel volumes has made traditional manual sorting methods insufficient. The DWS system sorter conveyor addresses this challenge by automatically capturing package dimensions, recording weight, and scanning barcodes in real time. This seamless integration reduces processing time while minimizing human error, providing logistics centers with reliable and accurate operational data.

At the core of the DWS system sorter conveyor is its ability to collect and synchronize critical shipment information. Advanced sensors measure the length, width, and height of parcels with high precision, while built-in weighing modules determine exact weight. Simultaneously, high-speed barcode scanners read shipping labels and transmit data directly to warehouse management systems. This synchronized data flow ensures accurate billing, route planning, and inventory tracking.

Logistics operators report significant improvements in throughput after implementing DWS system sorter conveyor technology. Distribution centers handling thousands of parcels per hour benefit from automated processes that reduce bottlenecks and enhance workflow consistency. The system not only improves sorting accuracy but also supports compliance with shipping standards and carrier requirements.

Another advantage of the DWS system sorter conveyor lies in its adaptability. Manufacturers design modular systems that can be integrated into existing conveyor lines, making upgrades cost-effective and scalable. Whether in e-commerce fulfillment centers, courier hubs, or cross-border logistics facilities, the system supports high-speed operations and flexible configurations.

The push toward smart logistics and digital transformation further fuels demand for DWS system sorter conveyor solutions. Real-time data collection allows companies to analyze performance metrics, optimize warehouse layouts, and improve forecasting accuracy. By leveraging automation and data integration, businesses can reduce operational costs while enhancing service reliability.

Sustainability considerations are also shaping system development. Efficient sorting reduces unnecessary handling and energy consumption, contributing to greener supply chain practices. Many suppliers are investing in energy-saving components and durable materials to ensure long-term operational stability with reduced environmental impact.

Experts predict that as parcel volumes continue to rise globally, the DWS system sorter conveyor will become a standard feature in modern logistics infrastructure. Its ability to combine precision measurement, automated sorting, and digital integration positions it as a key driver of efficiency in the evolving logistics landscape.

In conclusion, the DWS system sorter conveyor represents a significant step forward in logistics automation. By integrating dimensioning, weighing, and scanning into a unified system, it enhances accuracy, productivity, and data transparency. As supply chains grow more complex, this technology is expected to play a central role in shaping the future of smart logistics.

PREVIOUS: