Automated Data Capture Enhances Logistics Efficiency

Oct 21,2025

In the bustling environment of a modern warehouse or distribution center, accurately capturing parcel data is a fundamental step for shipping, invoicing, and inventory management. Manually measuring the dimensions and weight of countless boxes is a time-consuming and error-prone task. A technology designed to automate this process is the dimension weight scanning system, with the china newest static dws dimension weight scanning machine offering a focused solution for this critical operation.

This type of machine is typically installed at a fixed point in the intake area of a facility. The china newest static dws dimension weight scanning machine uses a combination of sensors, cameras, and scales to instantly capture a parcel's dimensions, weight, and barcode information as it is placed on the scanning platform. This integrated data capture replaces the need for multiple manual steps, streamlining the initial processing of incoming and outgoing shipments.

For logistics operators, the primary benefit is the significant gain in accuracy and speed. The data provided by the china newest static dws dimension weight scanning machine is used to calculate shipping costs accurately, especially for carriers that charge based on dimensional weight. This helps prevent revenue loss from incorrect measurements. Furthermore, the rapid processing reduces bottlenecks at the intake stage, allowing workers to focus on other value-added tasks.

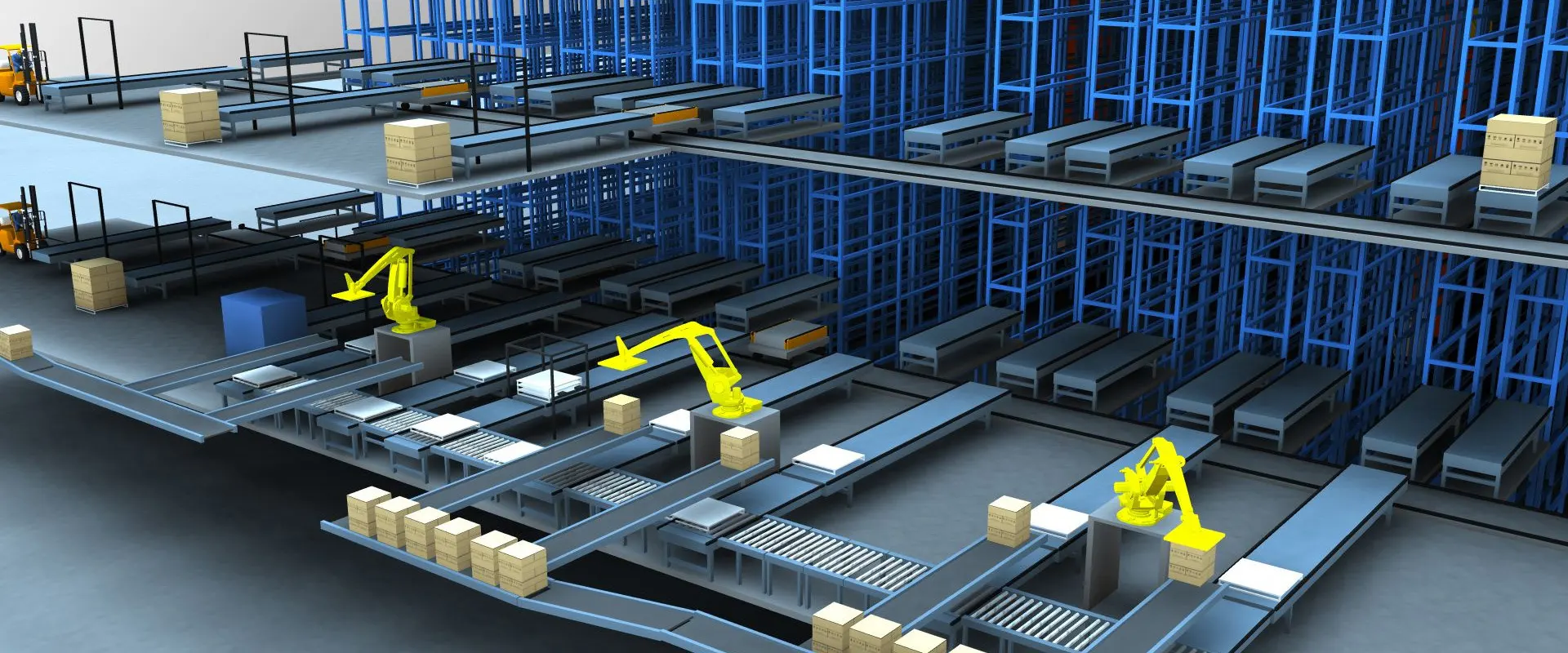

The role of this technology supports the broader trend of digitization in the supply chain. By providing reliable and instant parcel data, the china newest static dws dimension weight scanning machine forms a crucial data-gathering node within a larger automated logistics system. Its implementation is a practical step for businesses seeking to improve operational transparency, reduce costs, and enhance the overall efficiency of their shipping processes.