Optimizing Logistics with Automated Parcel Data Capture

Nov 04,2025

In the fast-paced environment of shipping and distribution centers, accurately processing parcel information is a fundamental task. Manually measuring boxes and weighing them is not only slow but can also lead to costly errors in shipping costs and inventory records. To address this, many facilities are implementing automated systems, with the china newest parcel dimension weight scale cube dws system providing an integrated solution for this essential operation.

This type of system is designed to capture key parcel data in a single step. The china newest parcel dimension weight scale cube dws system typically uses a combination of vision sensors, light curtains, and a precision scale to instantly measure a package's dimensions and weight while simultaneously scanning its barcode. This data is then used to calculate the dimensional weight (DIM weight), which is the billing method used by many major carriers, ensuring accurate and fair shipping charges.

For warehouse operators and logistics managers, the benefits are increased efficiency and data accuracy. The china newest parcel dimension weight scale cube dws system automates a previously manual and repetitive task, freeing up staff for other duties and significantly speeding up the intake process. The high level of accuracy helps prevent revenue loss from incorrect billing and improves the overall reliability of shipping data.

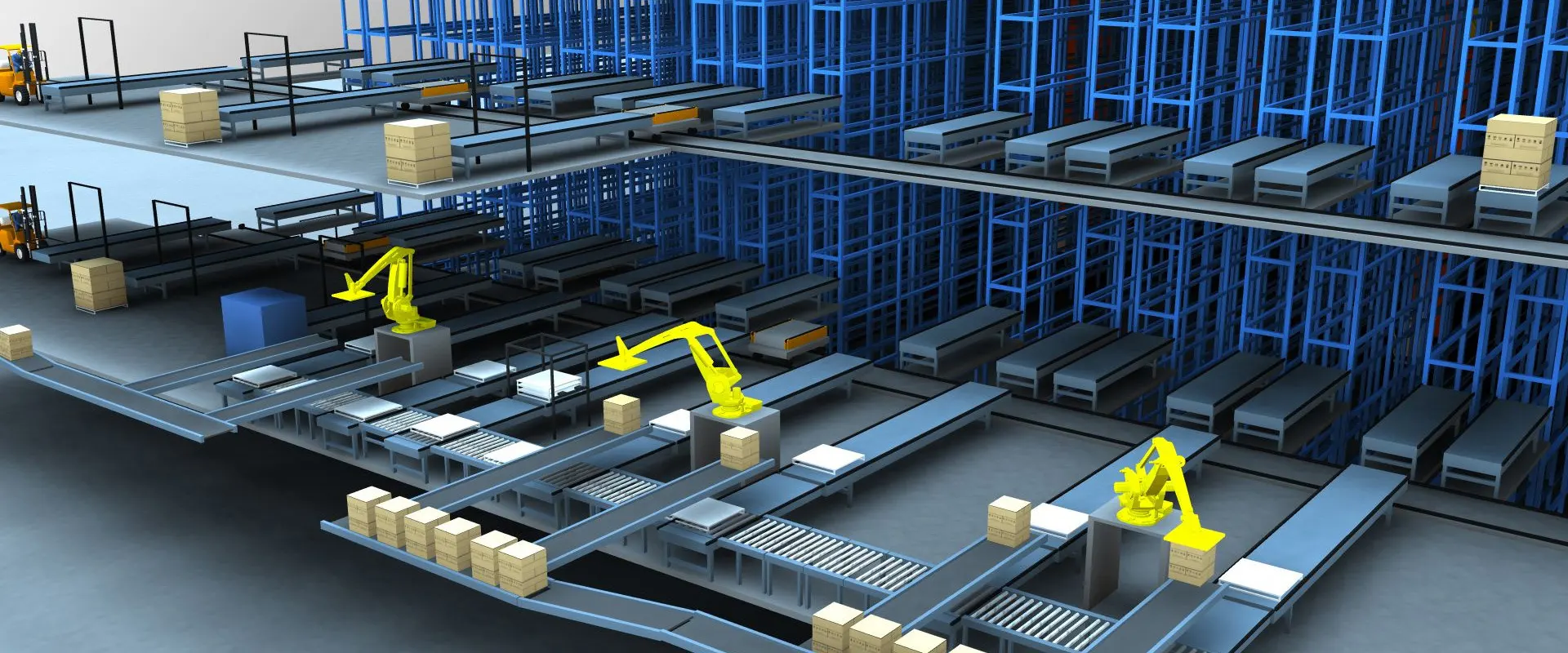

The role of this technology is becoming increasingly important as e-commerce volumes continue to grow. By providing a reliable and fast method for capturing critical parcel information, the china newest parcel dimension weight scale cube dws system serves as a key component in modernizing warehouse operations. Its implementation supports a more streamlined, data-driven, and cost-effective approach to managing the flow of goods in the supply chain.

PREVIOUS: