Streamlining Logistics with Integrated Dimensioning and Sorting

Oct 14,2025

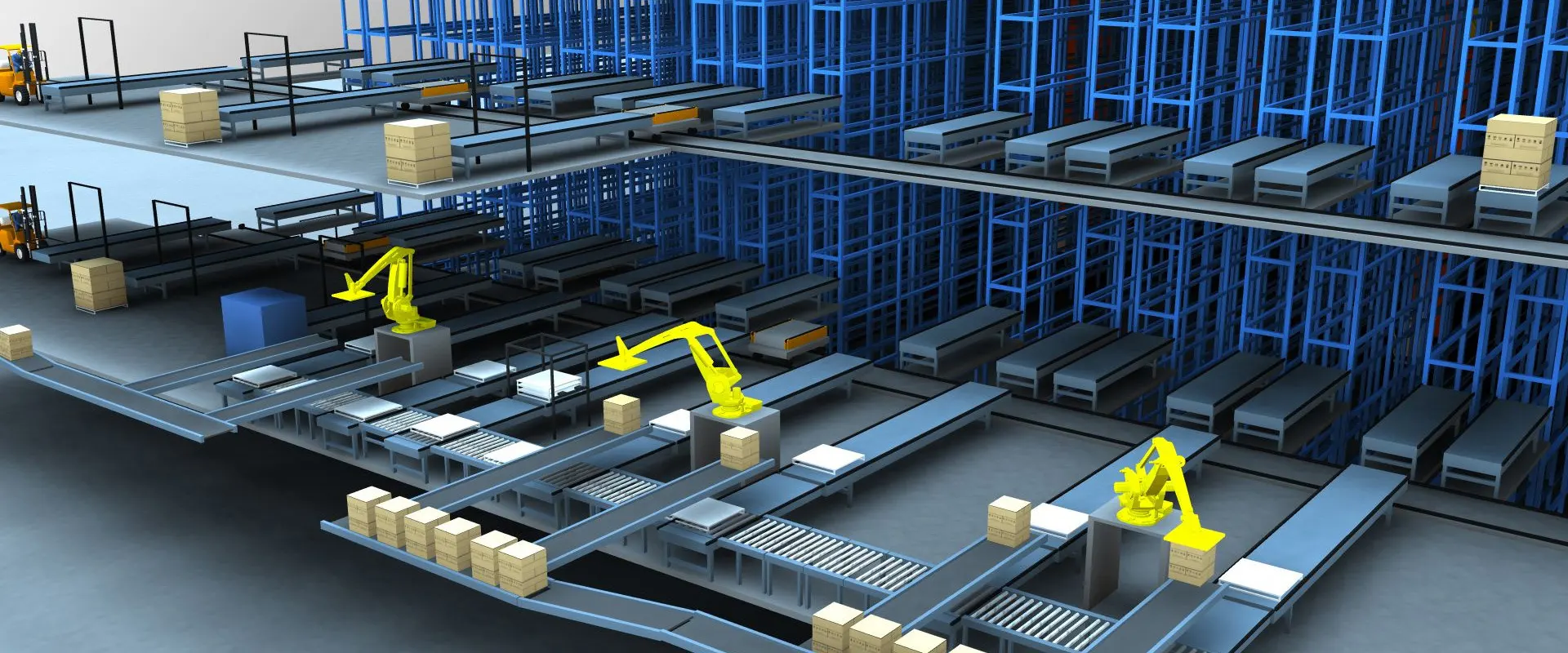

The rapid growth of e-commerce and global supply chains has placed unprecedented demands on logistics and distribution centers. A key bottleneck in these facilities has traditionally been the manual process of measuring parcels and routing them to the correct destination. To address this challenge, many operators are turning to automated solutions, with the china newest parcel sorting system with dws representing a significant step forward in warehouse efficiency.

The core of this technology is the Dimension, Weight, and Scanning (DWS) system. The china newest parcel sorting system with dws integrates these functions into a single, streamlined process. As a parcel moves along the conveyor, it is automatically scanned to capture its barcode, while sensors simultaneously measure its dimensions and weight. This data is instantly processed, eliminating the need for manual measurements and data entry, which significantly accelerates the intake and sorting process.

For warehouse managers, the benefits are increased throughput and reduced labor costs. The high-speed capabilities of the china newest parcel sorting system with dws allow a facility to handle a larger volume of parcels per hour with greater accuracy. The modular design of these systems also offers flexibility; they can be configured to meet the specific layout and volume needs of different warehouses. The ability to capture and archive images of each parcel adds a valuable layer of data for tracking and dispute resolution.

The implementation of such technology is becoming increasingly vital for logistics companies to remain competitive. By automating the critical steps of data capture and sortation, the china newest parcel sorting system with dws reduces errors and improves the overall speed of order fulfillment. This focus on integrated automation highlights a clear trend in the logistics industry towards smarter, more connected, and highly efficient material handling operations.