Enhancing Operational Flow in High-Volume Distribution

Jan 07,2026

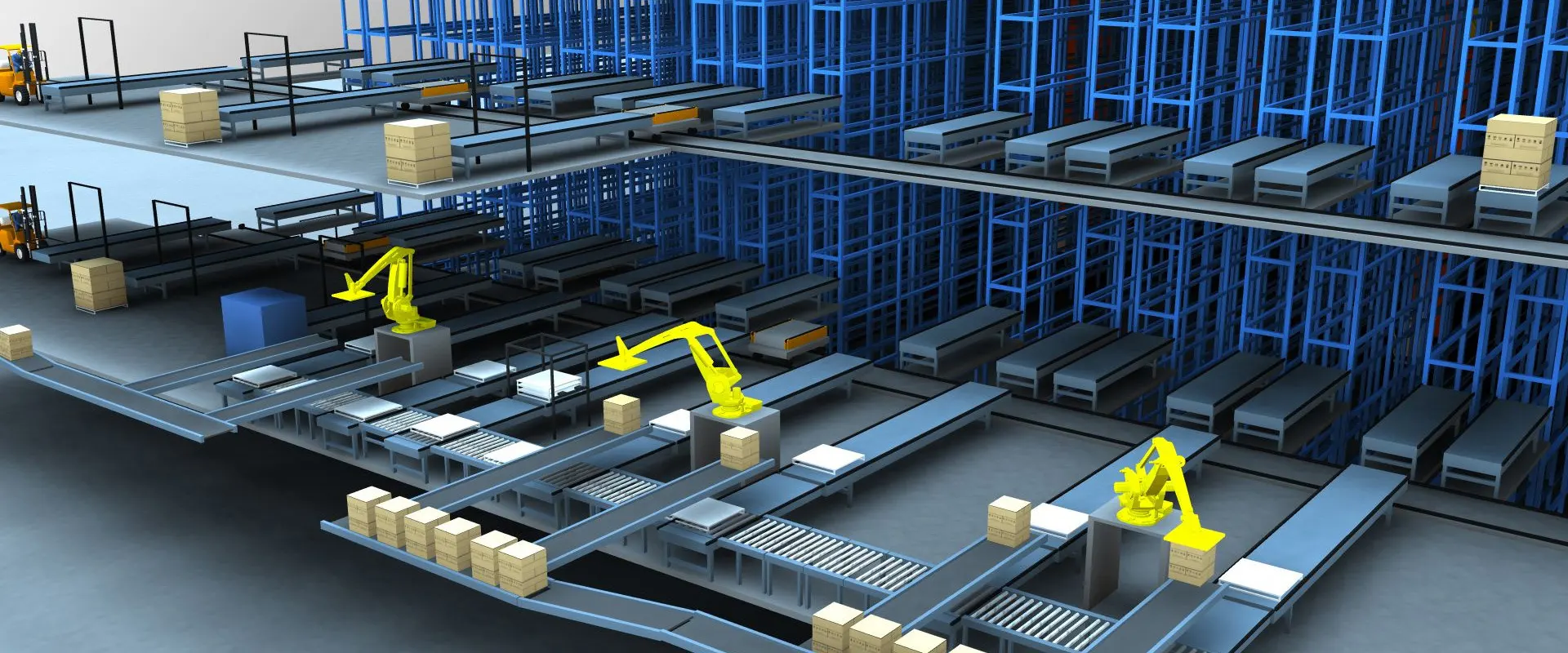

In modern logistics centers, the ability to swiftly and accurately direct a continuous stream of parcels to their correct destinations directly impacts delivery speed and service reliability. Manual sorting for thousands of items daily is not only labor-intensive but also prone to errors that can delay shipments. Automated systems have thus become a central feature in facilities aiming to maintain a smooth and dependable operational flow, ensuring packages keep moving efficiently from receiving to dispatch.

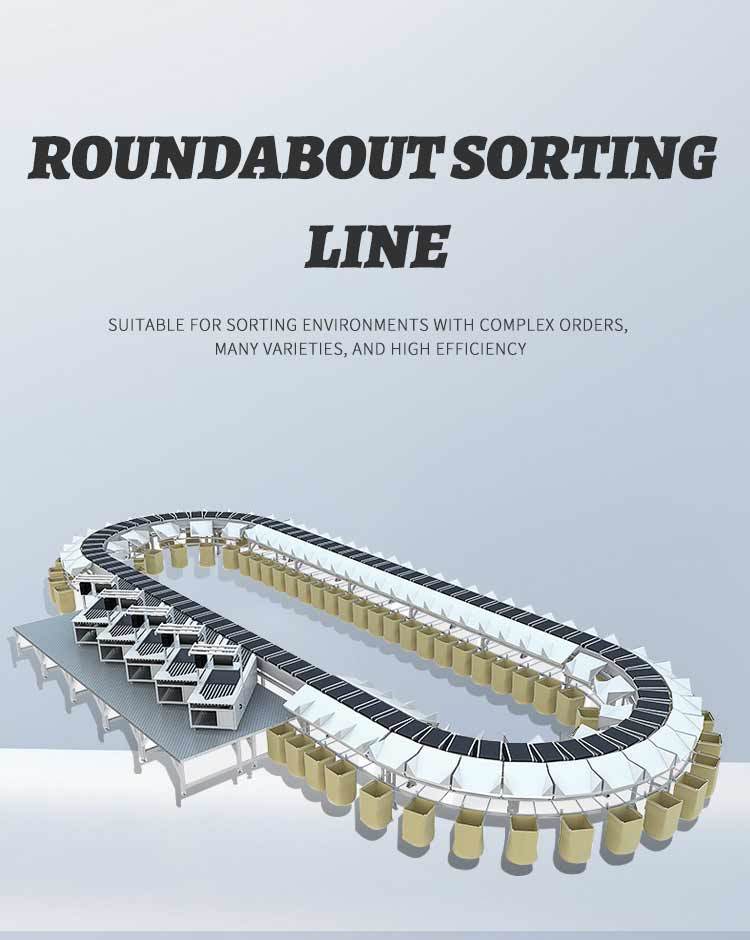

A system designed to address these demands is the high-efficiency circular sorting line. In our discussions with warehouse managers, the circular cross-belt design is often noted for its space-efficient layout, which allows for continuous operation within a compact footprint. With a sorting capacity reaching up to 24,000 parcels per hour and the ability to handle a diverse range of items—from small envelopes to larger boxes—this type of machine supports the varied product mix common in e-commerce fulfillment. Key technical parameters, such as a sorting error rate of 0.01% or less and barcode reading accuracy over 99%, translate into fewer mis-sorted items and reduced need for manual intervention, which teams on the ground appreciate for its contribution to daily throughput and order accuracy.

As order volumes fluctuate and business needs evolve, the flexibility of sorting equipment becomes as important as its base speed. The option to customize elements like the number of sorting chutes, carrier size, and line height allows a facility to tailor the system to its specific spatial constraints and parcel profile. This adaptability is crucial for long-term planning, making the choice of equipment provider a significant decision. For logistics operators looking to invest in such automation, partnering with a dependable quality sorting machine for parcels suppliers is a key step. A reliable supplier can ensure the system is correctly configured and integrates well with existing workflows.

The ongoing performance and uptime of the sorting line are vital for daily operations. This underscores the importance of sourcing from established quality sorting machine for parcels suppliers, who not only provide robust initial equipment but also support its integration and sustained operation. By doing so, distribution centers can build a more resilient and efficient sorting process, directly supporting timely deliveries and consistent service for their customers.