The Future of Automatic Conveyors

Aug 25,2025

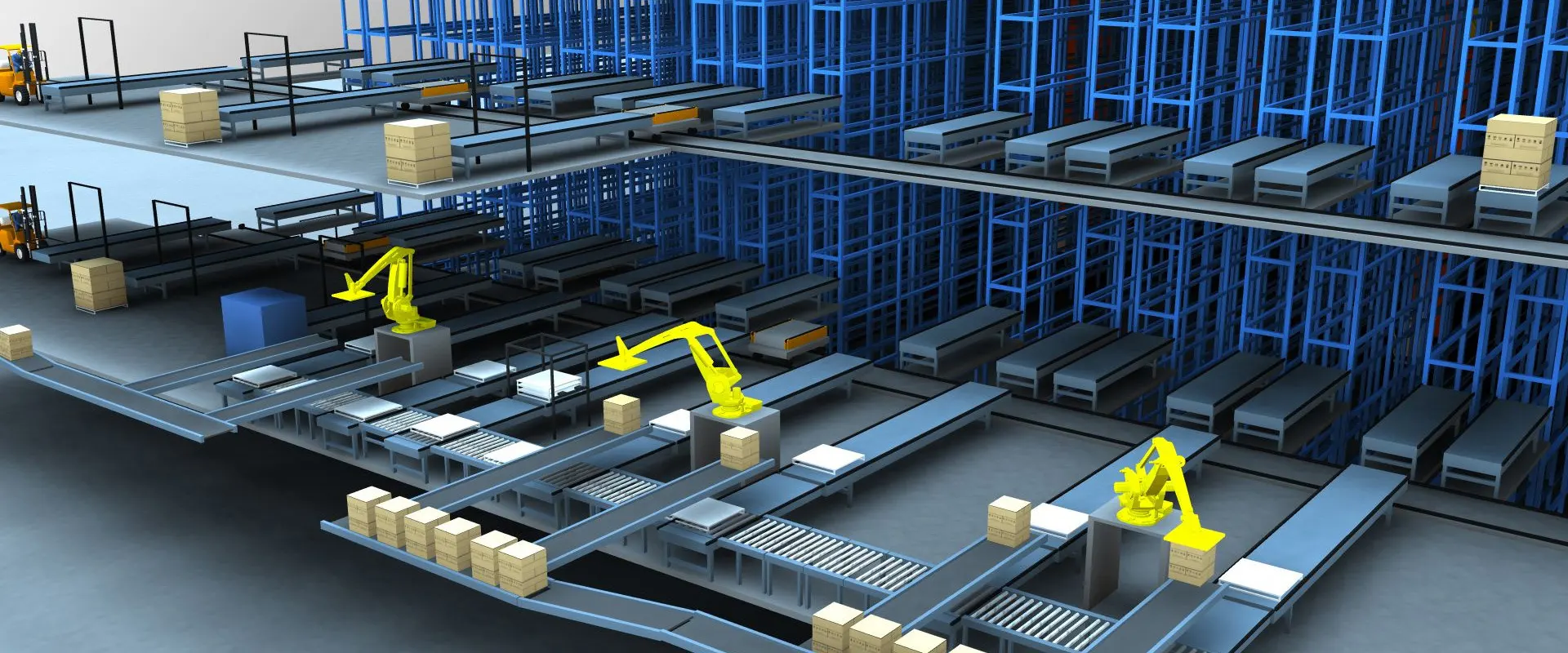

The field of automatic conveyors is constantly evolving, and the future holds great promise for these remarkable machines.

I. Integration with Smart Technologies

Automatic conveyors are increasingly being integrated with smart technologies such as the Internet of Things (IoT). Through IoT, conveyors can be connected to a central control system, allowing for real - time monitoring of their performance. Sensors on the conveyor can collect data about factors like speed, load capacity, and any potential malfunctions. This data can be transmitted wirelessly to a control room, where operators can make informed decisions. For example, if a conveyor is approaching its maximum load capacity, the system can automatically adjust the speed or divert some of the load to another conveyor to prevent overloading.

II. Customization and Flexibility

In the future, automatic conveyors will become more customizable to meet the diverse needs of different industries. Manufacturers will be able to design conveyors with adjustable speeds, widths, and configurations to suit specific production processes. For instance, in a multi - product manufacturing facility, the conveyor can be quickly reconfigured to handle different - sized and - shaped items. This flexibility will not only improve efficiency but also enable companies to adapt more easily to changes in production requirements.

III. Energy Efficiency

With the growing emphasis on environmental sustainability, the future of automatic conveyors will see a significant focus on energy efficiency. New designs will incorporate energy - saving motors and power - management systems. For example, conveyors will be able to automatically adjust their power consumption based on the load they are carrying. When the load is light, the conveyor can operate at a lower power level, reducing overall energy costs and environmental impact.

IV. Improved Maintenance and Durability

Advancements in materials science and engineering will lead to automatic conveyors with improved durability. Components will be made from stronger and more resistant materials, reducing the frequency of breakdowns. Additionally, predictive maintenance techniques will be more widely used. By analyzing the data collected from the conveyor’s sensors, maintenance teams can predict when a component is likely to fail and perform preventive maintenance. This will minimize downtime and keep the production process running smoothly.

As automatic conveyors continue to develop and adapt to new technologies and industry requirements, they will remain a vital part of modern manufacturing and logistics operations.