Telescopic Conveyors Enhance Efficiency in Loading Dock Operations

Nov 17,2025

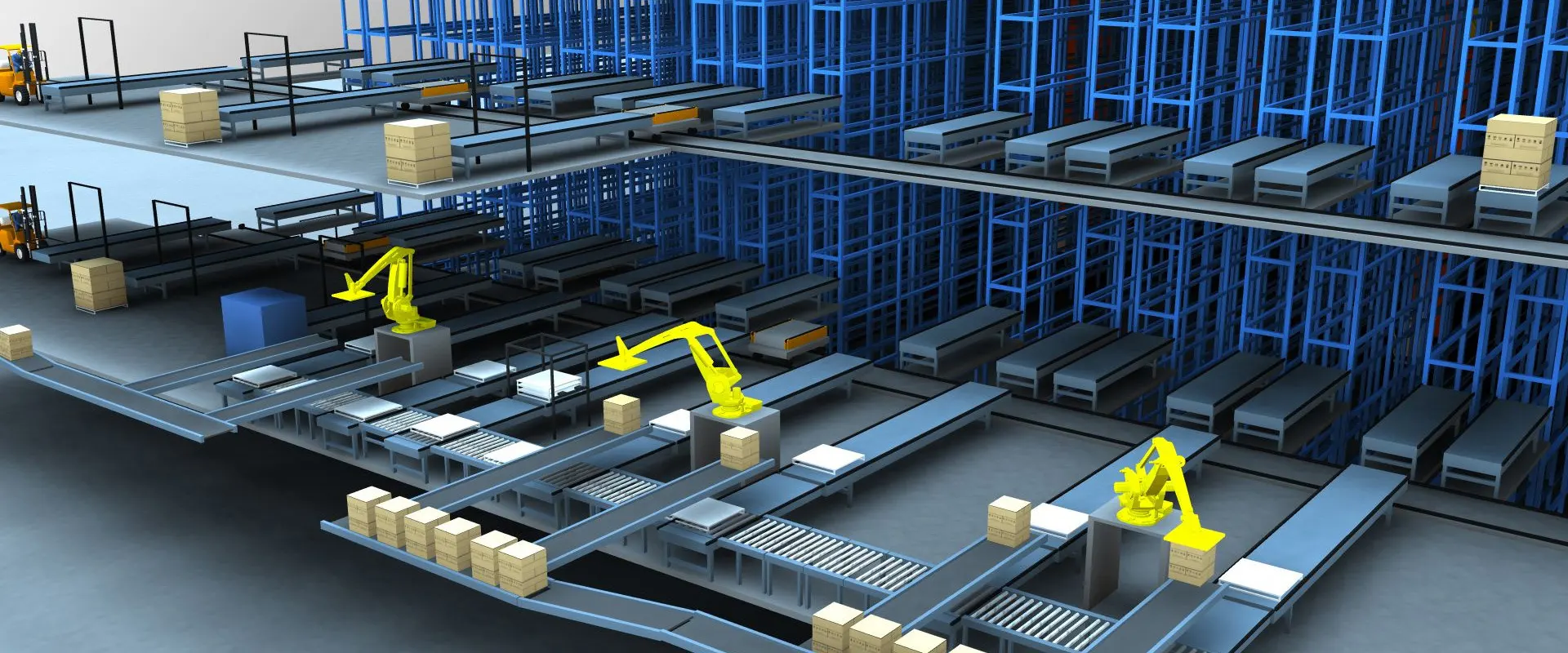

The loading and unloading of trucks at distribution centers and warehouses represent a critical point in the supply chain. This process is often physically demanding, time-consuming, and can be a source of product damage and worker injury. To address these challenges, many facilities are turning to automation, where the technology provided by a professional newest telescopic conveyor supplier offers a practical solution for improving both safety and throughput at the dock.

A telescopic conveyor, also known as an extendable or boom conveyor, is designed to reach directly into a truck trailer. Its key feature is the ability to extend and retract, allowing workers to place packages directly onto the moving belt at the point of loading, deep inside the cargo area. This eliminates the need for manual carrying over long distances. For a logistics manager, investing in a reliable system from a reputable newest telescopic conveyor supplier can lead to significant gains. It directly addresses ergonomic concerns by reducing bending and lifting, while also accelerating the entire loading/unloading cycle.

The operational benefits are substantial. By mechanizing the most labor-intensive part of the process, these systems can help decrease labor costs and minimize the risk of both product damage and worker strain injuries. The versatility to handle various package sizes and weights makes it a adaptable tool for diverse cargo. The role of an innovative newest telescopic conveyor supplier is to provide robust and user-friendly equipment that integrates seamlessly into existing dock operations. This technology represents a meaningful step towards more efficient, safer, and cost-effective material handling in modern logistics environments.