Efficient Sorting Systems Support High-Volume Logistics

Nov 20,2025

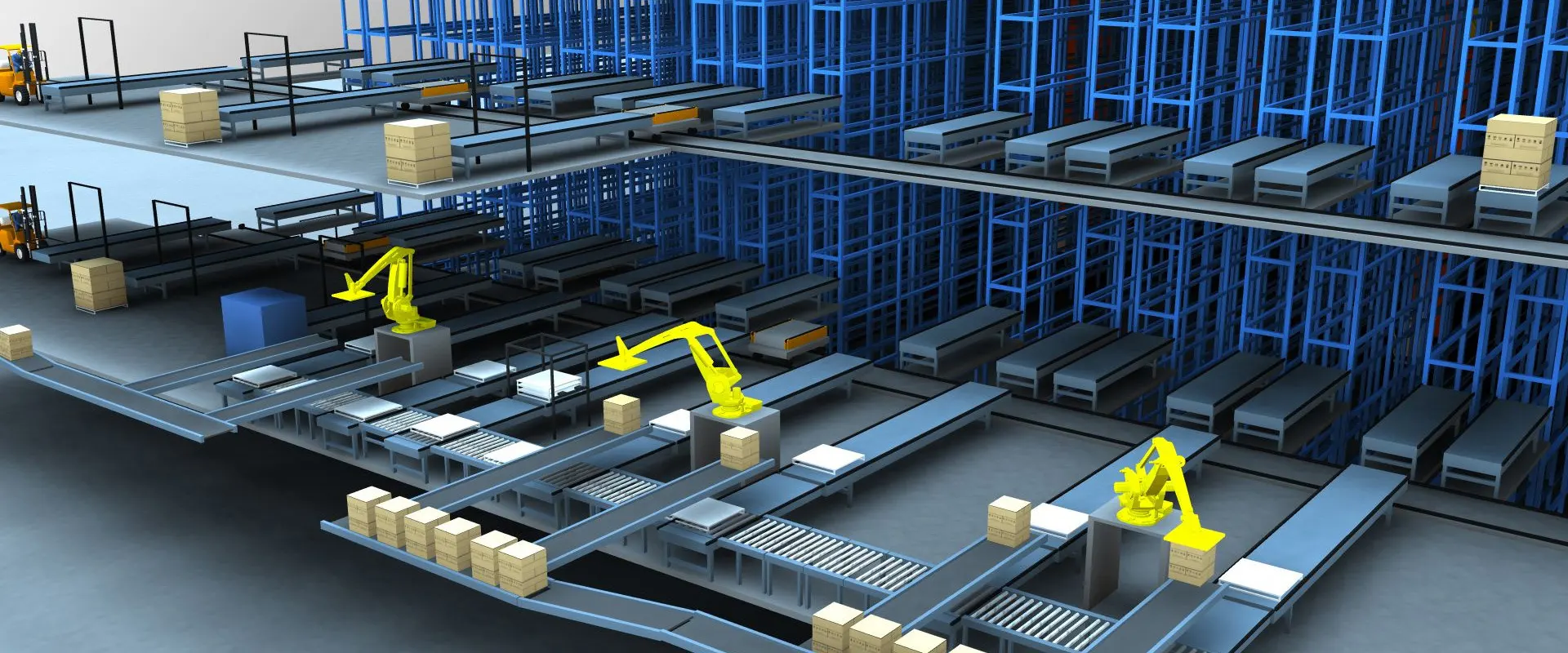

The relentless growth of e-commerce and global supply chains continues to push logistics centers toward greater automation. A central challenge in these facilities is the rapid and accurate diversion of a continuous stream of parcels to their correct destinations. To meet the demands of high-volume sorting, many distribution hubs are turning to advanced automated solutions, where the performance of a reliable quality ring sorting conveyor systems becomes a critical asset for operational success.

Unlike linear sorters, a ring sorter operates on a continuous loop, creating a highly compact and efficient sorting footprint. Individual carriers, often equipped with small cross-belts or pushers, travel along this oval or circular track. As each carrier passes a designated induction point, a parcel is loaded onto it. The system then transports the item to the correct outlet, where a mechanism gently discharges it. This design is a hallmark of a professional quality ring sorting conveyor systems, enabling the handling of thousands of items per hour with minimal manual intervention and a small physical footprint.

This technology is particularly effective for facilities managing a diverse mix of products, including fragile or irregularly shaped items that require careful handling. The continuous operation eliminates the downtime associated with the reciprocating motion of some linear sorters. The capabilities of a well-engineered quality ring sorting conveyor systems provide a scalable solution that can grow with a business. By offering a combination of high speed, gentle handling, and space efficiency, these systems are helping logistics providers meet the critical need for speed and accuracy in modern parcel distribution.

PREVIOUS: