Customize Sorting Conveyor Manufacturer Optimizes Logistics Operations

Dec 26,2025

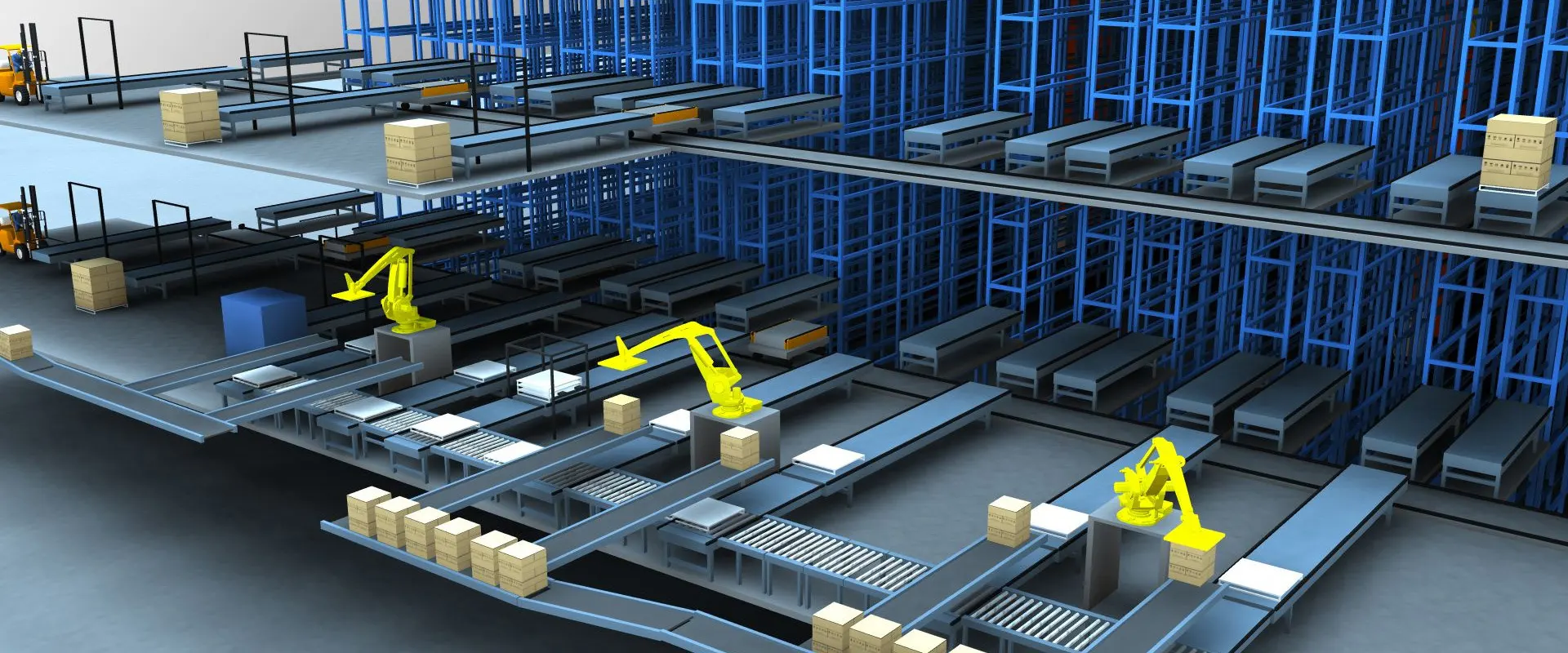

In the competitive landscape of e-commerce and logistics, the efficiency of a distribution center is directly linked to its ability to quickly and accurately sort parcels. A one-size-fits-all conveyor system often fails to meet the specific throughput, space, and product handling needs of a unique facility. This has led many warehouse managers and system integrators to seek more tailored solutions. Recognizing this demand, a growing number of businesses are now partnering with a specialized customize sorting conveyor manufacturer to develop systems that align precisely with their operational requirements.

The narrow belt sorter exemplifies the type of equipment that benefits greatly from customization. While its core function—using individual motorized belts to transport and divert items to specific chutes—is well-established, its implementation can vary. A knowledgeable customize sorting conveyor manufacturer can adjust key parameters. This includes modifying the conveyor length to fit the available building footprint, tailoring the divert mechanism's force and speed for specific product weights, or adjusting the belt width and spacing to handle a particular mix of box sizes and irregular items common to that warehouse.

This collaborative approach yields significant practical benefits. For the operations team, a system designed for their specific workflow minimizes bottlenecks and maximizes the use of floor space. It can also reduce product damage by ensuring handling mechanisms are calibrated correctly. By working directly with a manufacturer to tailor the system, companies achieve a higher degree of integration, which often results in smoother operation, easier maintenance, and better long-term scalability as their sorting needs evolve. This strategic partnership moves beyond simple equipment purchase to creating a core material handling asset that is a direct extension of the facility's unique logistics strategy.