Wheel Sorter Conveyor Systems Improve Speed and Flexibility in Automated Sorting

Feb 20,2026

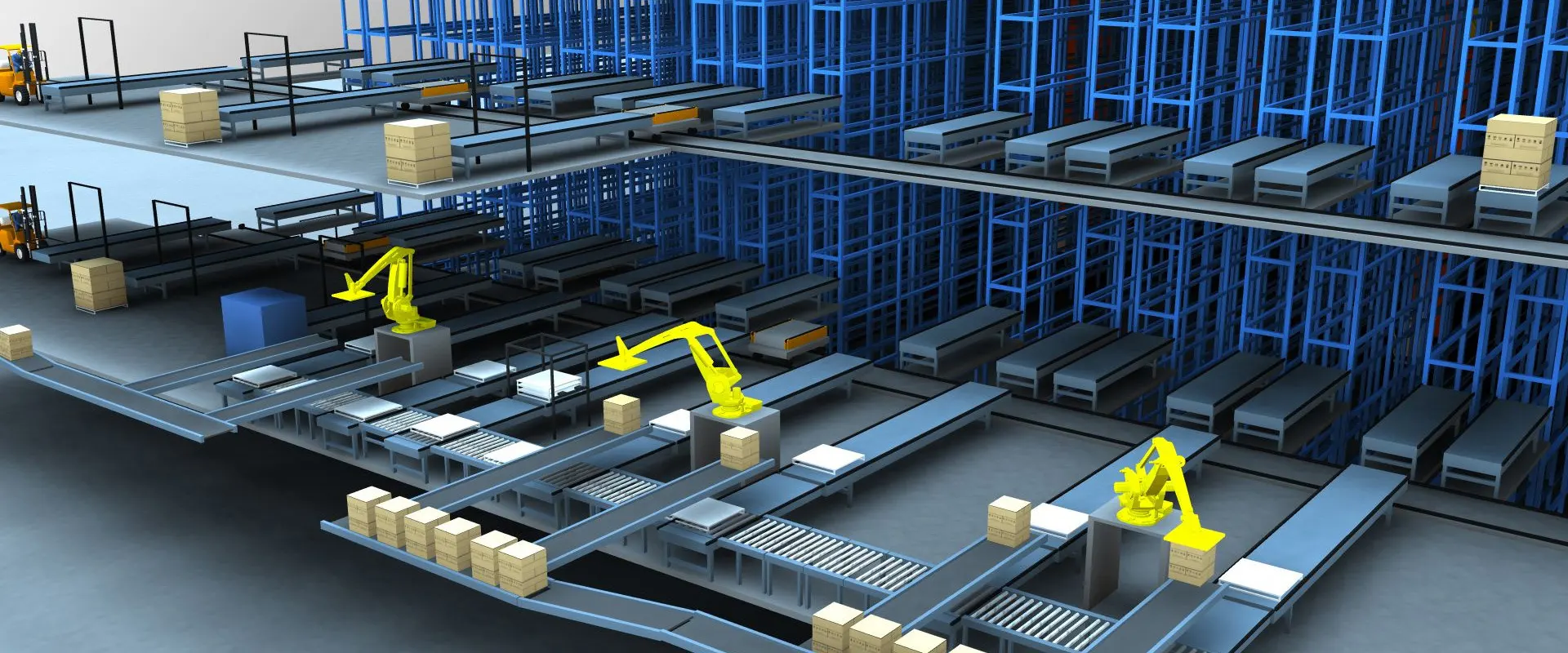

As automation continues to reshape the logistics and distribution industry, the wheel sorter conveyor has become an increasingly popular solution for fast and flexible parcel sorting. Known for its compact structure and high responsiveness, the wheel sorter conveyor is widely used in warehouses, distribution centers, and e-commerce fulfillment facilities where efficient material flow is critical.

A wheel sorter conveyor is an automated sorting system that uses rows of powered wheels embedded in a conveyor bed. These wheels rotate at controlled angles and speeds to divert items smoothly from the main conveyor line to designated destinations. When packages reach a sorting point, the wheels activate instantly, guiding items sideways onto chutes or takeaway conveyors without stopping the main flow. This design enables continuous, high-speed sorting while maintaining stable operation.

One of the key advantages of a wheel sorter conveyor is its ability to handle a wide variety of items. From cartons and parcels to flat packages and polybags with rigid bases, wheel sorter systems can process diverse products efficiently. The rolling contact surface provides gentle handling, reducing impact and minimizing the risk of product damage during sorting. This makes the wheel sorter conveyor suitable for industries such as retail, apparel, electronics, and express logistics.

Speed and responsiveness are defining characteristics of wheel sorter conveyor systems. Because the wheels can be activated independently and rapidly, sorting decisions are executed in real time. This allows the system to achieve high throughput rates and adapt quickly to changing order patterns. During peak periods, such as holiday seasons or promotional campaigns, wheel sorter conveyors help facilities maintain consistent performance and avoid congestion.

Space efficiency is another important benefit. Wheel sorter conveyors typically feature a low-profile, modular design that can be integrated into existing conveyor lines with minimal layout changes. Their compact footprint allows for multiple sort points to be installed within limited space, helping warehouses maximize capacity without expanding their physical facilities.

From an operational standpoint, wheel sorter conveyor systems contribute to cost efficiency and labor optimization. Automated sorting reduces reliance on manual handling, lowers error rates, and improves workplace safety. At the same time, simple mechanical structures and durable components support reliable operation and easier maintenance, resulting in lower total cost of ownership over time.

Looking forward, wheel sorter conveyors are increasingly being integrated with advanced control systems and warehouse management software. Real-time tracking, system diagnostics, and data analytics enhance visibility and enable predictive maintenance. These smart features further improve uptime and ensure that wheel sorter conveyor systems remain aligned with the evolving demands of modern logistics.

In summary, the wheel sorter conveyor is a practical and efficient solution for automated sorting applications. By combining speed, flexibility, gentle handling, and space-saving design, it helps logistics operations improve throughput and accuracy while maintaining adaptability in a rapidly changing supply chain environment.

PREVIOUS: