Parcel Sorting Conveyor: Revolutionizing Package Handling

Jul 29,2025

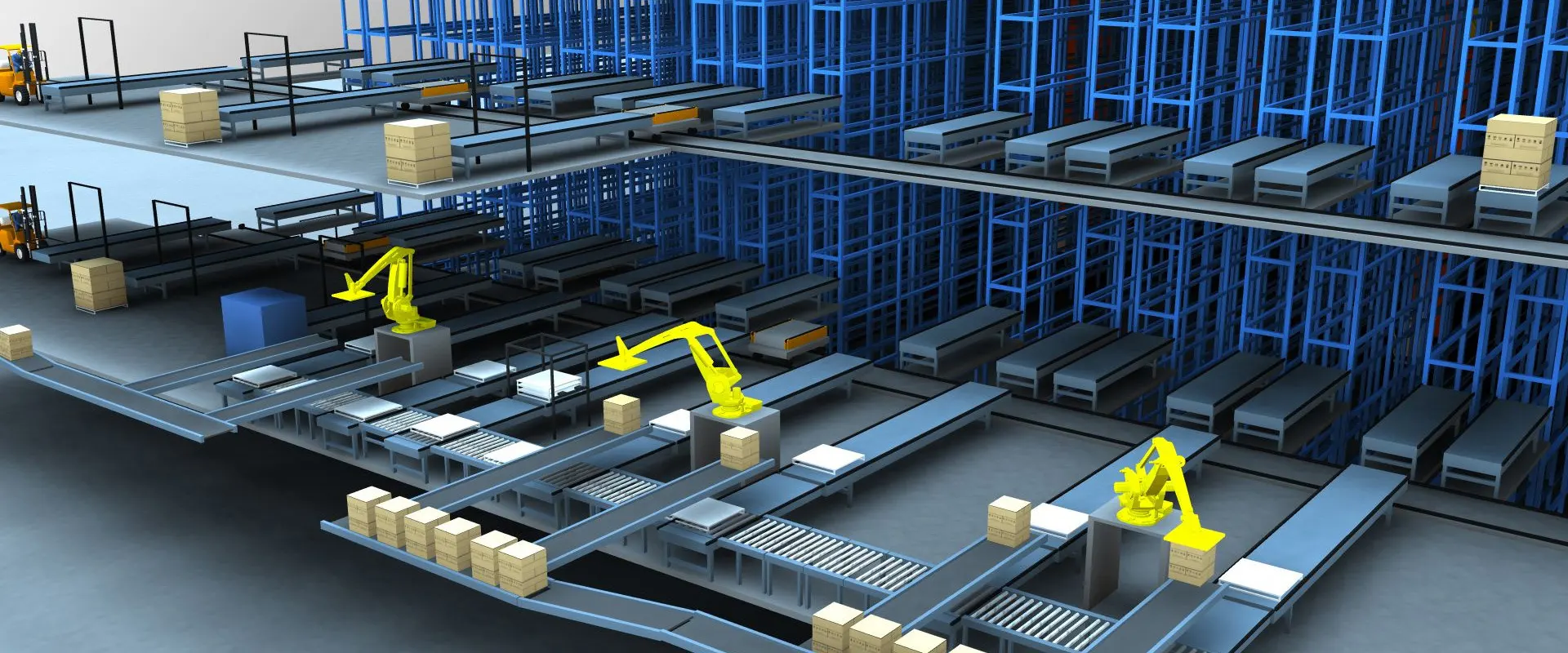

In the fast - paced world of logistics and e - commerce, the parcel sorting conveyor is an indispensable piece of equipment.

1. Design and Structure

The parcel sorting conveyor typically features a robust and durable construction. It is made of high - quality materials such as stainless steel or heavy - duty alloys to withstand the continuous movement of parcels. The conveyor belt is designed with a non - slip surface to ensure that parcels are transported smoothly without slipping or getting stuck. The length and width of the conveyor can be customized according to the specific requirements of different sorting facilities. It often consists of multiple sections, including straight segments and curved segments, which can be arranged in a variety of layouts to fit into the available space.

2. Sorting Mechanism

One of the key features of the parcel sorting conveyor is its advanced sorting mechanism. It can be equipped with sensors, such as barcode scanners or RFID (Radio - Frequency Identification) readers. When a parcel passes through the scanning area, the sensor reads the unique identification code on the parcel. Based on this information, the conveyor system can then direct the parcel to the appropriate destination. This is achieved through a series of diverters or sorting gates. These gates can be controlled electronically and can accurately divert parcels to different chutes or conveyor branches, enabling efficient sorting based on factors like destination address, parcel size, or delivery priority.

3. High - Speed and Efficiency

The parcel sorting conveyor is designed to operate at high speeds. It can handle a large volume of parcels per hour, significantly increasing the productivity of sorting facilities. For example, in a large e - commerce distribution center, it can sort thousands of parcels during peak hours. The continuous and seamless operation of the conveyor ensures that there are no bottlenecks in the sorting process, reducing the overall processing time for parcels. This high - speed operation also helps to meet the tight delivery schedules that are common in the modern logistics industry.

4. Flexibility and Adaptability

This type of conveyor is highly flexible and adaptable. It can be integrated with other logistics equipment, such as automated storage and retrieval systems (AS/RS) and palletizers. It can also be adjusted to handle different types of parcels, from small envelopes to large boxes. The software that controls the conveyor can be updated easily to adapt to new sorting algorithms or business requirements. For instance, if a new delivery destination is added or if the sorting criteria change, the system can be quickly reconfigured without major hardware modifications.

5. Safety Features

Safety is a top priority in the design of parcel sorting conveyors. It is equipped with safety guards to prevent operators from coming into contact with moving parts. Emergency stop buttons are installed at strategic locations along the conveyor so that in case of any abnormal situation, the entire system can be halted immediately. Additionally, the conveyor is designed to operate within a certain noise level limit to provide a relatively quiet working environment for the operators.

In conclusion, the parcel sorting conveyor plays a crucial role in the modern logistics and e - commerce sectors. Its efficient sorting capabilities, high - speed operation, flexibility, and safety features make it an essential investment for any company involved in parcel handling and distribution.

PREVIOUS: