Expansion belt conveyor installation and commissioning steps

Mar 25,2025

Expansion belt conveyor installation and commissioning steps

At present, the telescopic belt conveyor is widely used in logistics, express delivery, grain transportation and other industries. Because its installation accuracy is not like precision equipment such as machine tools and large motors, the installation conditions are very high, so some users will choose to do it themselves.

However, the installation of the telescopic belt conveyor is not completely without precision requirements. Because once the installation is faulty, it will bring unnecessary trouble to the subsequent debugging work and acceptance work. And in the use of production, it is also easy to cause accidents such as belt deviation.

The following is a brief introduction to how to correctly install and debug the telescopic belt conveyor, which is roughly divided into the following steps.

Preparations before installation:

First of all, familiarize yourself with drawings. Through the drawing, we can master the structure of the product, the way of installation, the composition and quantity of parts, performance parameters and other important information. Then, familiarize yourself with the important installation dimensions and technical requirements on the drawings.

Since there may not be a large enough site to move during the installation, it is necessary to pick out the installed equipment, mark it, and set the installation position for lifting. After the lifting is in place, the installation site should be investigated to eliminate the unfavorable factors affecting the lifting and installation of the equipment. When installing, try to find out all the equipment to be installed and used, and lift it in place once, which not only saves the cost of the crane, but also improves the work efficiency.

Telescopic belt conveyor installation steps:

Whether the telescopic belt conveyor can run smoothly after installation mainly depends on the installation accuracy of the drive device, drum and tail wheel. Whether the center of the telescopic belt conveyor bracket coincides with the center line of the drive device and the tail wheel.

Drive installation:

Pay-off can be marked between the head (drive device) and the tail (tail wheel) by the theodolite, so that the center line between the head and the tail is connected into a straight line, and this method of pay-off can ensure high installation accuracy.

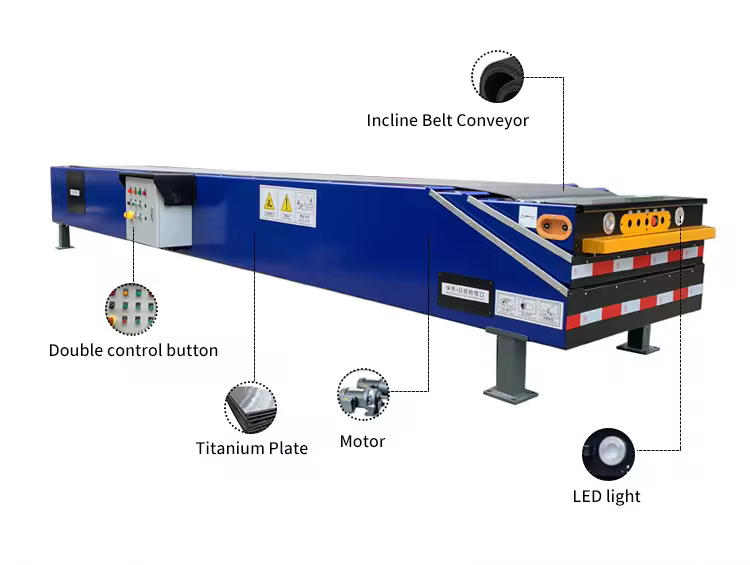

The installation drive device is mainly composed of motor, reducer, driving drum, bracket and so on.

First of all, we assemble and place the driving drum and bracket on the embedded plate, place a steel pad between the embedded plate and bracket, and use a level to level the bracket to ensure that the levelness between the four points of the bracket is less than or equal to 0.5mm.

Then, find out the middle branch line of the driving drum, place the line drop on the middle branch line, and adjust the longitudinal and transverse middle branch line of the driving drum to coincide with the base center line.

When adjusting the elevation of the driving drum, it is also necessary to consider reserving a certain margin for the adjustment of the elevation of the motor and reducer. Since the connection between the motor and the reducer has been adjusted on the bracket when the equipment is manufactured, our task is to find the alignment, leveling, and ensuring the coaxiality between the reducer and the drive drum.

When adjusting, take the driving drum as the basis, because the reducer and the driving drum are connected to the nylon rod elastic connection, the accuracy of the coaxiality can be appropriately relaxed, adjusted to the radial less than or equal to 0.2mm, and the end face is not greater than 2/1000.

Installation of tail wheel and drum:

The tail wheel is composed of two parts: the bracket and the drum, and the adjustment steps are the same as the driving drum.

Most of the legs of the belt conveyor are H-shaped, and their length and width are different according to the length and width of the belt and the amount of belt transportation.

Installation of accessories and safety devices:

The installation of accessories can only be carried out after the belt is placed on the bracket. Accessories include empty section cleaner, head cleaner, anti-deviation switch, belt tightening device, etc.

After the operation of the above methods and steps, and to ensure a certain accuracy range, through the no-load and load test, positive and negative direction test run, and adjust the belt deviation, you can run smoothly and safely.

Telescopic belt conveyor commissioning steps:

After the telescopic belt conveyor is properly installed, it also needs to be carefully adjusted to ensure smooth operation.

Whether the tension is normal or not directly affects the use effect and service life of the conveyor. If the tension is too loose, the conveyor belt will run off, and if the tension is too tight, it will affect the service life of the belt, and even cannot turn or the belt will jump up and down when it is turned.

Debugging and installation of the belt conveyor, we must first adjust the parallelism and levelness of the belt, the parallel is not good will form the uneven force of the belt, the levelness is less than the belt deviation.

When starting, the point mode should be used, and the speed should be gradually adjusted to the required speed after starting, usually the running speed should reach 60% of the limit speed.